- New

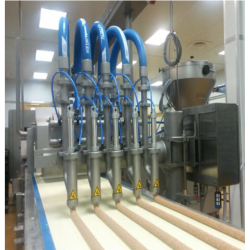

FILLER KF

Contract price

PRECISE DOSING, FLEXIBLE IN USE.

UPC:

EAN13:

Description

Modular design, up to 32 dosage units. Versatile use for liquid and pasty products. Examples: Natural yoghurt, fruit yoghurt, cottage cheese, soft cheese, curd cheese, cream cheese, honey, jam, butter, margarine, mayonnaise, ketchup, etc.

TECHNICAL DATA

- 8, 12, 16, 24 or 32 dosing units

- Dosing capacity from 10 to 500 ml

- filling accuracy: +/- 0,5% per cycle

- Maximum product temperature: 80° C

- Up to 4 products can be processed simultaneously

- Compensator and / or filling hopper

- Filling nozzle plate

- CIP programs / CIP valves

- Non-drip filling nozzles

- Reverse suction for liquid products

- Clear arrangement and good accessibility

- Refittable as add-on filler

- Control: Simens S7

- Server drive

220 other products in the same category:

- New

Filling & Stuffing machines

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

Contract price

Highly corrosive product rotary pressure overflow filler

- New

Ice Cream Filling Machine BG-2

- New

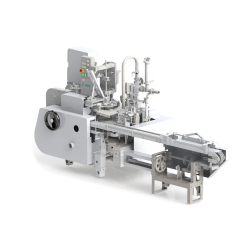

FME 50 (Rotary Form-, Fill- and Seal Machine)

- New

ARM-B2/B3 - BUTTER FILLING AND WRAPPING MACHINE

- New

Filling & Stuffing machines

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

Price

€3,459.00

- New

Can filling station ELEMENTRA 14

- New

FSL 48 Form, fill and seal lines

- New

- New

In-Line-Filler SERVOFI LL F100

- New

MINI form, fill and seal machine

- New

Casing filling machine SR 90N

- New

AR2T - CURD FILLING AND WRAPPING MACHINE

- New

Washers, Cleaners & cip systems

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

Contract price

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

Piston filler 2-100 ml P 100

- New

Spoon Honey Filling And Capping Machine

- New

FS 37 Form, fill and seal lines

- New

EMF - MULTIPLE WRAPPING MACHINE

- New

Bagging and filling machine – VBA

- New

Automatic can filler INTEGRA 606 + 608

- New

ECOFILL HT2 Semi-automatic filling machine

- New

FC-25 Sausage Fillers / Stuffers

- New

ICEPACK - Linear Filling Machines

- New

ARM - BUTTER FILLING AND WRAPPING MACHINE

- New

ARU - PROCESSED CHEESE FILLING AND WRAPPING MACHINE

- New

Filling & Stuffing machines

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

Contract price

- New

Filling & Stuffing machines

DABL series automatic aseptic plastic bottle filling and capping machine

Contract price

- New

Hydraulic Filling Machine DF 250 X

- New

ICEPACK - Rotary Filling Machines

- New

Jam Filling Machine DUPLEX 150

- New

RFS 40 - TUB / CUP FILLING MACHINE

- New

Automatic groups vacuum fillers-seamer

- New

Filling & Stuffing machines

GF series automatic plastic bottle filling and capping production line

Contract price

- New

Cheese - Volumetric Filling

- New

Manual honey filling unit 0NRG.38

- New

Hydraulic sausage fillers VINS/22

- New

Pressure overflow bottle filler - model GI 3300

- New

RFS 120 - CUP / TUB FILLING MACHINE

- New

Automatic groups piston-filler seamer

- New

Semiautomatic filling machines

- New

Automatic can filler INTEGRA 64

- New

Bottle Filler Innofill Glass Micro DPG

- New

Filling & Stuffing machines

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

Contract price

- New

FL-D.L.M. linear mass flow dosing machine

- New

Bagging and filling machine – VLRB

- New

Vertical form fill sealing

- New

- New

Coffee Capsule Filling And Sealing Machine

- New

Packaging & Sealing equipment

TPM 1000 fully automatic thermoforming packaging machine

Contract price

TPM 1000 fully automatic thermoforming packaging machine

- New

CONTINUOUS VACUUM FILLER F9

- New

Filling & Stuffing machines

Vertical form-fill and seal machine of the “Economy” series

Contract price

- New

SP-10 JUSPER Introduction

- New

ORG - BULK BUTTER FILLING MACHINE

- New

PET filler Innofill PET NV

- New

Filling & Stuffing machines

Filling and seaming groups for aluminium and tin plate cans

Contract price

- New

Ketchup Filling, Capping and Labeling Machine

- New

Opti 100 Vacuum Stuffer & Pump

- New

ARG - ICE CREAM FILLING AND WRAPPING MACHINE

- New

Piston bottle filler - model PI3300

- New

Bottle reject model 1900-002

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT