- New

ProBloc Label-Fill-Cap

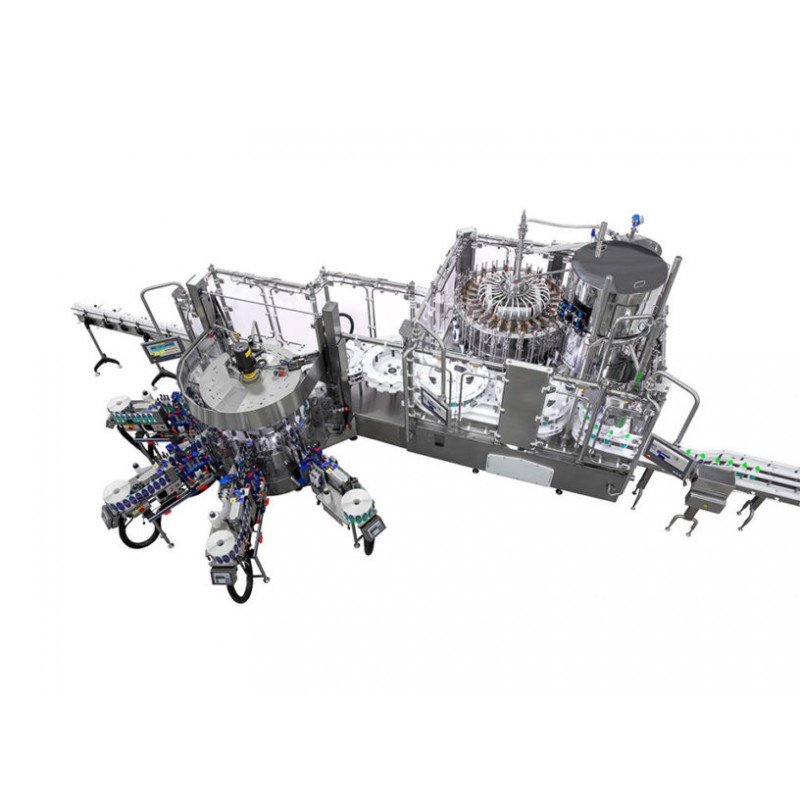

ProBloc™ is a high-efficiency integrated tri-bloc system for light to semi-viscous liquid personal care products.

Description

ProBloc™ is a high-efficiency integrated tri-bloc system for light to semi-viscous liquid personal care products. It can be configured for 8 oz. (236 mL) to 32 oz. (946 mL) containers with speeds up to 400 cpm.

ProBloc is offered through and supported by ProMach Filling Systems.

Each ProBloc system performs three key packaging functions:

- Labeling

- Filling

- Capping

As an integrated bloc system that labels containers prior to filling and capping, ProBloc provides higher operating efficiencies and lower scrap costs than separate pieces of equipment performing the same functions.

All supplied technologies are designed, manufactured and supported by best-in-class ProMach brands:

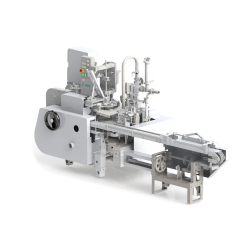

- P.E. Labellers: Pressure sensitive labeling systems

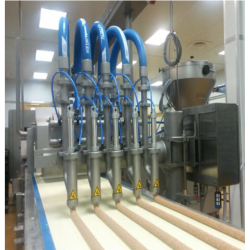

- Pacific & Federal fillers: Flow meter, volumetric time pressure, weight or level

- Zalkin capping systems: Screw-on, roll-on, push-in and snap-on

ProBloc systems are configured with labeling, filling and capping capabilities tailored to each customer’s requirements.

For more information, call ProMach Filling Systems at + 1 (844) 838-1704, email us at ProBloc@ProMachBuilt.com or complete and submit the form on this webpage.

Features & Benefits

- Labeling empty – Labeling empty containers with an inspection / no fill / rejection system dramatically reduces filled container scrap costs and yield loss.

- Space efficient – Bloc design reduces overall equipment footprint and saves valuable floor space.

- Smooth, optimized container handling – Bloc starwheel to starwheel container flow optimizes control through the labeling, filling and capping process.

- Tool-less container changeovers – Color coded, no tool change parts make container changeovers simple to execute.

- 4-axis adjustment of pressure sensitive labeling heads - Assures precise label application.

- Internal barrier enclosures – Stainless steel and polycarbonate panels shield and protect the labeling station from the filling station during production and CIP.

- One call support – ProBloc is supported by a dedicated team of highly trained ProMach technicians. Technical support for labeling, filling and capping systems is one phone call away.

220 other products in the same category:

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

- New

- New

- New

- New

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

- New

- New

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

- New

- New

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

- New

DABL series automatic aseptic plastic bottle filling and capping machine

- New

GF series automatic plastic bottle filling and capping production line

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT