- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

Contract price

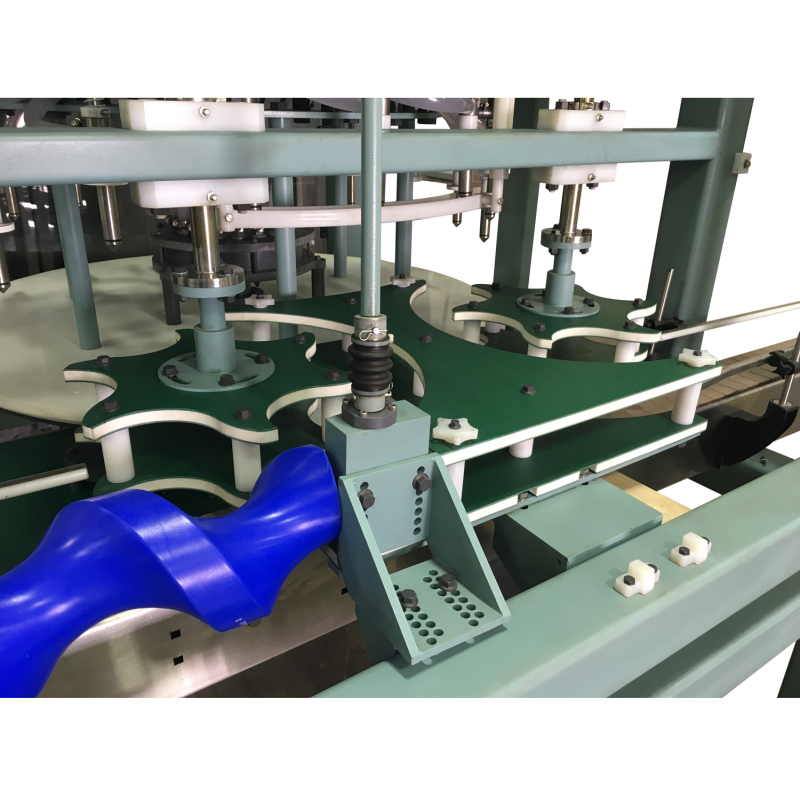

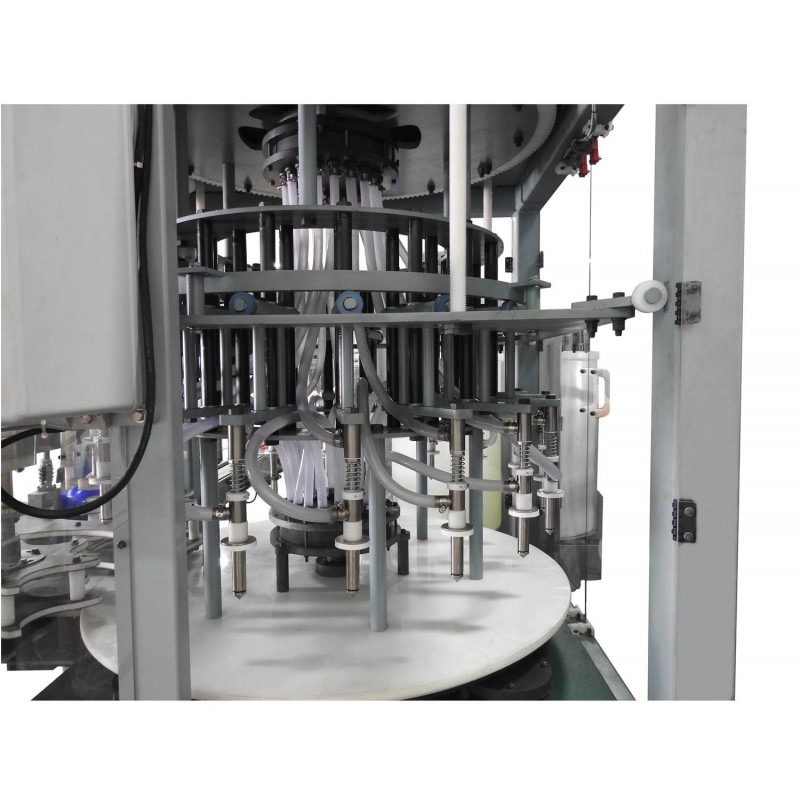

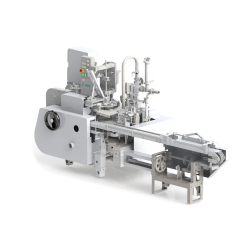

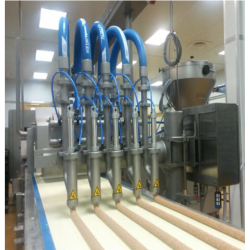

ACASI Rotary pressure–overflow filler model RF48-18-BL, automatic 18 head rotary filler for corrosive product

Reference:

Highly corrosive product rotary pressure overflow filler

UPC:

EAN13:

New product

Description

Construction features:

- 304 Stainless steel heavy duty stainless steel epoxy painted for corrosion resistance.

- 304 stainless steel cam with corrosion resistant bushings and cam followers.

- Supply and return manifold made in titanium.

- Calibrated guide for fast height changeovers.

- Leveling of machine by 1 inch screws, corrosion resistant.

- Includes drip pan made of corrosion resistant materials.

Control panel features:

- Omron PLC for all machine logic functions, special modifications on programs available for special adaptations.

- Frequency control drive for pump speed, acceleration and deceleration.

- Front panel bottle filling time adjustment through Omron Timer.

- Front panel conveyor speed control for machine sold with conveyor.

- Front panel mounted bottle counter.

- Front panel Start and Emergency STOP for easy access.

- Front panel nozzle code for changing nozzle quantities.

- Fiber optic sensors by Omron standard for container gating.

- Expandable to 20 nozzles to increase speed.

- No bottle no fill PLC controlled.

Transmission features:

- Gears located on top of the movement for better maintenance.

- All bearings protected with seals to prevent corrosion.

- Manual height adjustment with position indicator.

Manifold features:

- Top and bottom manifold independent.

- Manufactured in CP2 Titanium or PVC according to product.

- Triple teflon loaded seals to prevent leaks.

Main components feature:

- Corrosion resistant magnetic drive centrifugal pump - PVDF construction and EPDM seals with variable speed controlled on main panel.

- 100 gallon polyethylene satellite tank for feed, product return and product supply with level control

- Lexan Safety enclosure with safety switches.

- No bottle no fill.

Container handling:

- Infeed screw and starwheel assembly for each container.

- 18 filling positions.

- Tool-less changeover parts and adjustments.

- Distance between centers 8.4in.

Conveyor:

- 16 feet total length conveyor, raised bed.

- Stainless steel motor.

- Enclosure to prevent splashing to gearbox.

- Titanium or Zirconium conveyor shaft drive.

Control panel features:

- Omron PLC for all machine logic functions, special modifications on programs available for special adaptations.

- Frequency control drive for pump speed, acceleration and deceleration.

- Front panel conveyor speed control for machine sold with conveyor.

- Front panel mounted bottle counter.

- Front panel Start and Emergency STOP for easy access.

- Fiber optic sensors by Omron standard for backup sensor.

Electric and pneumatic requirements:

- 220 Volts, 50Hz or 60Hz, 20 Amps.

- 5 CFM @ 80 p.s.i.

220 other products in the same category:

- New

Piston bottle filler - model PI3300

- New

ECOFILL HT2 Semi-automatic filling machine

- New

Manual honey filling unit 0NRG.38

- New

Filling & Stuffing machines

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

Contract price

- New

ARG - ICE CREAM FILLING AND WRAPPING MACHINE

- New

FL-D.L.M. linear mass flow dosing machine

- New

ARM - BUTTER FILLING AND WRAPPING MACHINE

- New

AR2T - CURD FILLING AND WRAPPING MACHINE

- New

Automatic groups vacuum fillers-seamer

- New

ARM-B2/B3 - BUTTER FILLING AND WRAPPING MACHINE

- New

ARU - PROCESSED CHEESE FILLING AND WRAPPING MACHINE

- New

Jam Filling Machine DUPLEX 150

- New

Bagging and filling machine – VLRB

- New

Automatic can filler INTEGRA 64

- New

Pressure overflow bottle filler - model GI 3300

- New

Bottle reject model 1900-002

- New

Automatic groups piston-filler seamer

- New

SP-10 JUSPER Introduction

- New

Casing filling machine SR 90N

- New

Filling & Stuffing machines

GF series automatic plastic bottle filling and capping production line

Contract price

- New

Filling & Stuffing machines

Vertical form-fill and seal machine of the “Economy” series

Contract price

- New

CONTINUOUS VACUUM FILLER F9

- New

- New

Filling & Stuffing machines

DABL series automatic aseptic plastic bottle filling and capping machine

Contract price

- New

MINI form, fill and seal machine

- New

RFS 120 - CUP / TUB FILLING MACHINE

- New

FSL 48 Form, fill and seal lines

- New

Filling & Stuffing machines

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

Price

€3,459.00

- New

RFS 40 - TUB / CUP FILLING MACHINE

- New

EMF - MULTIPLE WRAPPING MACHINE

- New

Bottle Filler Innofill Glass Micro DPG

- New

Bagging and filling machine – VBA

- New

ICEPACK - Rotary Filling Machines

- New

FS 37 Form, fill and seal lines

- New

ORG - BULK BUTTER FILLING MACHINE

- New

Cheese - Volumetric Filling

- New

Spoon Honey Filling And Capping Machine

- New

Ice Cream Filling Machine BG-2

- New

- New

Filling & Stuffing machines

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

Contract price

- New

Automatic can filler INTEGRA 606 + 608

- New

Packaging & Sealing equipment

TPM 1000 fully automatic thermoforming packaging machine

Contract price

TPM 1000 fully automatic thermoforming packaging machine

- New

FC-25 Sausage Fillers / Stuffers

- New

In-Line-Filler SERVOFI LL F100

- New

PET filler Innofill PET NV

- New

Hydraulic Filling Machine DF 250 X

- New

Opti 100 Vacuum Stuffer & Pump

- New

Ketchup Filling, Capping and Labeling Machine

- New

ICEPACK - Linear Filling Machines

- New

Coffee Capsule Filling And Sealing Machine

- New

Can filling station ELEMENTRA 14

- New

Filling & Stuffing machines

Filling and seaming groups for aluminium and tin plate cans

Contract price

- New

Piston filler 2-100 ml P 100

- New

Semiautomatic filling machines

- New

Vertical form fill sealing

- New

Washers, Cleaners & cip systems

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

Contract price

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

FME 50 (Rotary Form-, Fill- and Seal Machine)

- New

Hydraulic sausage fillers VINS/22

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT