- New

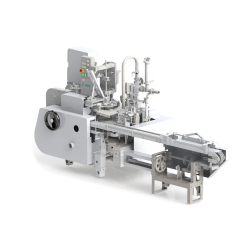

P 100 Forming, filling and sealing for portion packs

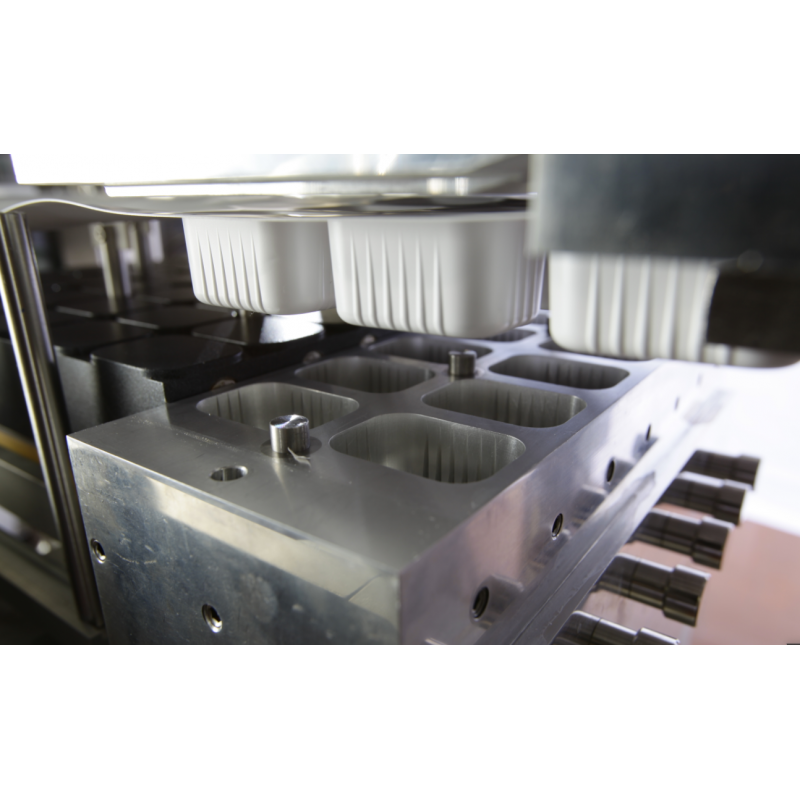

The P100 is the entry machine for portion packs. It's a compact and modular form, fill and seal machine for mini-portions for multiple food and dairy applications. Offering efficiency at low operational costs.

Description

The entry machine for portion cups.

The P100 is a high quality form, fill and seal machine for mini-portions in low output range for filling products like butter, margarine, sweet spread, jam, dressings and sauces, etc.

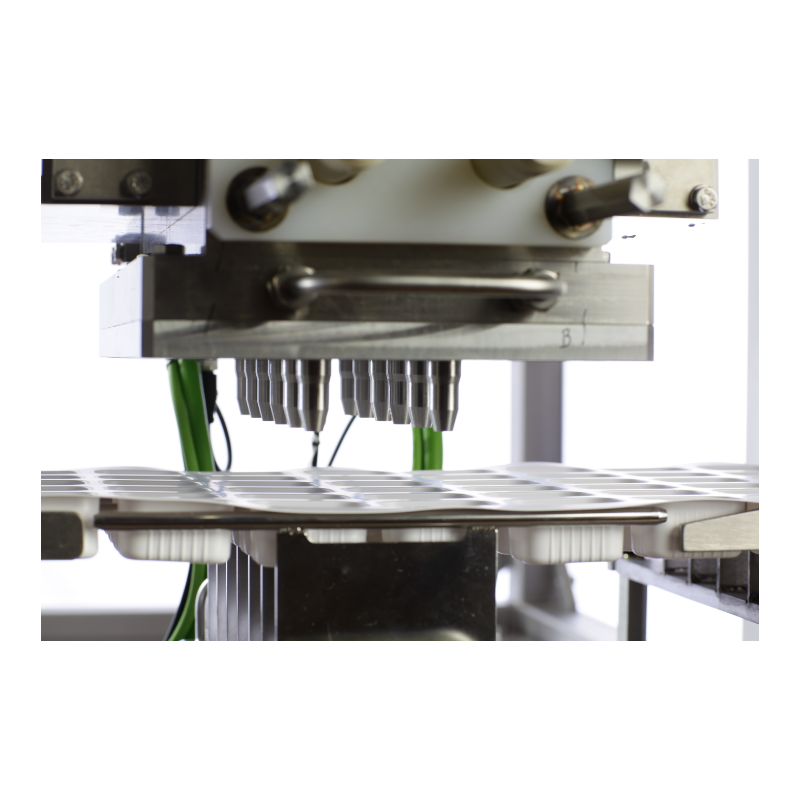

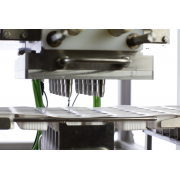

With a minimal footprint, modular structure and reduced web level height for convenient handling, the P100 ensures accurate processing, precise product cut-off and gentle product handling.

The machine is characterized by its‘ compact design, an excellent accessibility, high availability and low total cost of ownership.

P100 Highlights

1. Small footprint.

2. For portion cups in low output range.

3. Maximum accuracy, precise product cut-off and gentle product handling.

4. Servo driven dosing piston for ease adjustments.

5. Large variety of cup shapes and designs.

Products to be filled in portion cups

The convenient portion cups can be used to fill butter, desserts, cream cheese, soft cheese, ketchup, mustard, mayonnaise, sauces, jams, honey, spreads, dressings, etc.

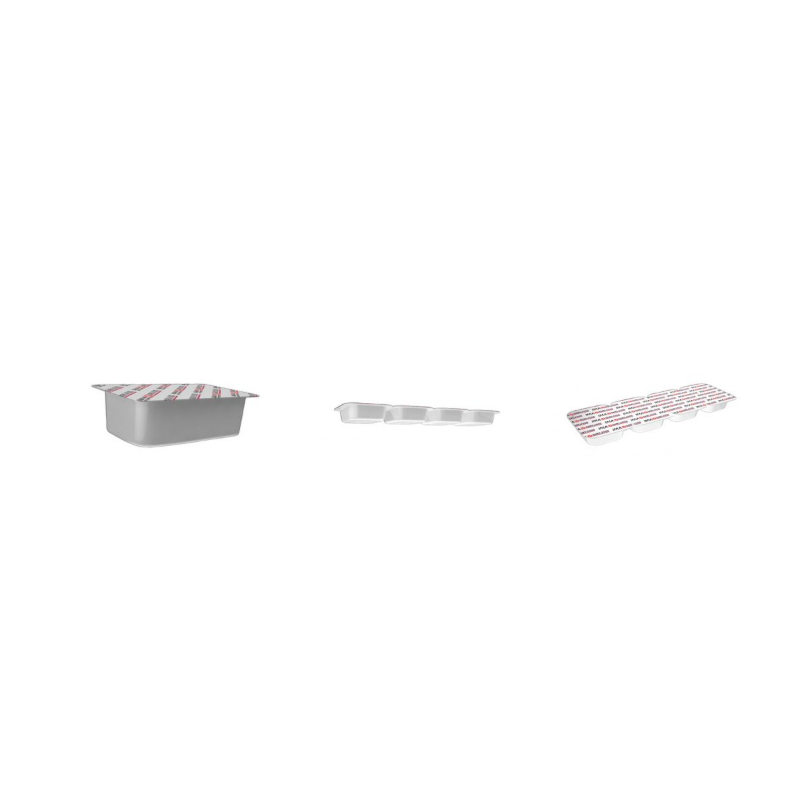

Cup shapes for portion cups

Different kind of cup shapes are available for portion cups.

| TECHNICAL DATA P 100 | |||

| Cup material width | 300 mm | Draw off length | max. 150 mm |

| Usable width | 284 mm | Forming depth | max. 40 mm |

| MATERIALS | |||

| All common packaging materials | |||

| Bottom web | PS | ||

| Lidding foil | Paper/PET, PET, Alu/PET, PET/Alu/PE | ||

| TYPICAL OUTPUTS | |||

| Portion cups 12-up, 30 cycles/min. | 21,600 cups/h | ||

| Portion cups 8-up, 30cycles/min. | 14,400 cups/h | ||

| portion cups 6-up, 30 cycls/min. | 10,800 cups/h | ||

| STANDARDS | |||

| Components | Controller and servo motors ELAU, Pneum. FESTO, HMI 15” | ||

| Standard configuration | Bottom web reel Ø 1000 mm Lid web reel Ø 300 mm conveyor, single press, servo driven |

||

| Hygiene | Clean | ||

| OPTIONS | |||

| Hygiene | UVC decontimination, lamiar flow | ||

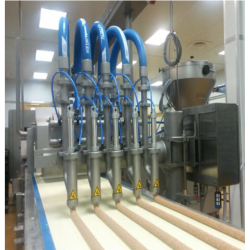

| Filler | 1 filler, CIP-able, compensator, agitator | ||

| Punching options | wasteless punching | ||

| Others | PVC, PET-Options, grid punch, walking beam, case packer | ||

- Made from: Stainless steel

220 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

- New

- New

- New

- New

- New

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

- New

- New

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

DABL series automatic aseptic plastic bottle filling and capping machine

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

- New

- New

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT