- New

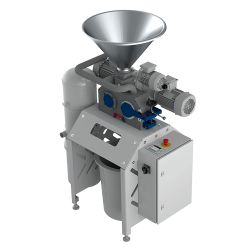

HILLER CONDITIONER

Continuous crushing of solids in a high performance conditioner to generate an optimal suspension for the decanter.

Description

HILLER PROCESS

The product to be crushed is fed into the conveyor scroll via a funnel or similar. This transports it evenly into the conditioner. Crushing is carried out here with maximum cell breakdown via freestanding beaters. The variable use strainer determines the grain size distribution of the suspension produced. This can be fed to the downstream pump via a collection container.

BENEFITS - HILLER TECHNOLOGY

■ optimal cell breakdown for best

possible yield

■ simple replacement of the strainers

■ product temperatures over 90°C

possible

■ rotors and beaters can be rotated

to increase the service life

FEATURES

■ high performance conditioner with

reinforced bearings and shaft

■ infinite speed control via frequency

converter

■ large selection of strainer inserts

■ additional product and additive

options

■ processing under protective

gas possible

■ option for direct steam feed

■ cost-effective wearing parts and

simple replacement

■ optimal supplement to HILLER food

grade decanters

■ explosion hazard area version

available for dry products

APPLICATIONS

■ milling of herbs and spices

■ extract preparation in the aroma industry

■ manufacture of mixtures for the tea industry

■ mash preparation for the juice industry

■ puréeing of frozen, dried or water-based products

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT