- New

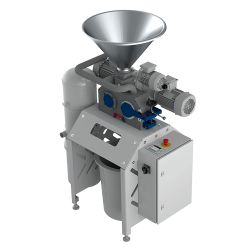

ROBOEdge

ROBOEdge Fully Automated Sharpening System

Description

Creates the perfect sharp edge, every time!

Take the guesswork out of grinding, honing, and polishing all hand knives with the fully automated ROBOEdge knife sharpening system from PRIMEdge.

The ROBOEdge increases efficiency of processing operations while achieving a low total cost of ownership. The robotic sharpening system uses minimal parts and durable, long-lasting materials—and requires only one operator.

Capable of sharpening at least 65 knives an hour, operators can simultaneously refurbish other dull tools or conduct other tasks. The system also eliminates downtime with dual retractable drawers that allow one tray to be loaded while the other tray is being sharpened. In less than 50 seconds, each knife is hollow ground, honed, polished, and returned to the tray as the next knife is selected.

The ROBOEdge achieves accurate blade thinning, precision honing, and edge polishing in four simple steps:

Knife Recognition

An automated four-axis knife clamping system selects and holds the knife while the knife recognition system identifies the blade profile, thickness, and any bends which controls the sharpening process based on the information detected.

Hollow Grinding

Blades are hollow ground under a constant flow of coolant with proprietary synthetic cup stone wheels that ensure the proper grind in a single pass. The stones self-adjust when needed to maintain consistent spacing between stones for an accurate grind on both sides of the blade.

Honing/Edging

The blade is then edged and honed with PRIMEdge’s proprietary spiral stones, made to sharpen at angles from 22 to 45 degrees. Two spiral honing wheels automatically adjust and are timed to perfectly sharpen a cutting edge.

Polishing

Any burrs or grind striations are removed as both the hollow grind and cutting areas are polished at the same time guaranteeing a smooth cut and reducing resistance for all types of applications.

Features

- Knife recognition system identifies the blade profile and any bends•

- Ensures a proper Hollow Grind in a single pass

- Accurately sharpens at angles from 22 to 45 degrees

- Hollow grind bevel and cutting edge polished at the same time

- Self-adjusting stones eliminates need to dress

- Dual Tray Loading System ensures continuous sharpening

- Easily programmable cutting angle adjustment

- Pneumatic Grippers go up to 100kg of pressure on the knife handle

- Heavy duty frame protects operator and machine

- Photocells assures protection for the operator and avoids any interference while in operation

Technical Info

System is CE approved

Dimensions

Width = 3220 mm / 127 in

Depth = 2905 mm / 115 in

Total Height = 2900 mm / 114 in

Supplies required

- Electrical 440/220 V 60 Hz 3 Phases + Ground 50/70 Amps

- Compressed Air 6 bars

Electrical and electronic

- Electrical panel includes all electrical components and is installed inside the machine frame

- High frequency PLC

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT