- New

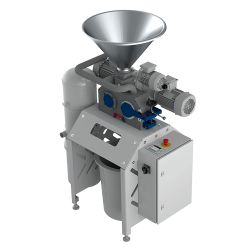

REDUNIT

Contract price

THE CUSTOMIZED AND MODULAR GRINDING SYSTEM

UPC:

EAN13:

Sold By:

view_listView more products of this seller

Description

- Individual engineering unit

- Compact and sturdy

- High availability thanks to quick and easy service

- Added safety due to cartridge mechanical seal technology

- Low electricity consumption

The RedUnit is a combination between grinders and pumps. Depending on the needs of the respective industrial application, the RedUnit can have only one grinder for a coarse particle reduction, a grinder plus pumps for a further conveying of the media, or even several grinders with pumps for a much defined particle reduction.

FEATURES

108 other products in the same category:

- New

CHOCOCON 150 chocolate / compound processing unit

- New

Industrial pre-rotating grinder IR 250

- New

CM18 roasted seeds and nuts pre-grinder

- New

PC-82 / PC-22 Meat Mincers (Grinders)

- New

Refrigerated meat mincer with automatic feeding C/E901 R

- New

- New

Grinding / Milling Dry Pasta Scraps

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT