- New

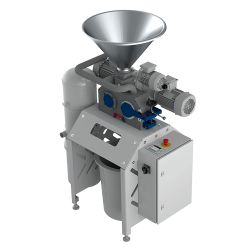

GD 93-3 inline grinding system

Filling and grinding in a single step with the VF 600

Description

Product and cost optimisation with inline grinding system technology

With the Handtmann GD 93-3 inline grinding system technology, the product is ground to its final grain size and simultaneously portioned in one process step. The main advantage of grinding to the product's final size in this way is the reduced number of process steps. Independently controlled feeding and separating drives facilitate flexible adaptation of the cut size. The optional use of a gristle separator ensures product reliability.

Sausage production is its strength

The strengths of inline grinding system technology are demonstrated in particular when it is used in conjunction with AL systems for sausage production. The tried-and-tested combination of VF 600 vacuum filler (especially the VF 622 and VF 628 with high filling pressure up to 72 bar) and the GD 93-3 inline grinding system is the solution specifically designed for products which are difficult to process. It brings key quality advantages for the production of minced meat and minced meat products, fresh sausage, dry sausage and small-calibre dry sausage snacks.

Premium quality minced meat with inline grinding system technology

In conjunction with the GD 93-6 minced meat attachment and GMD minced meat portioner, the GD 93-3 inline grinding system is the system solution for efficient, high-quality minced meat production.

Inline grinding system technology integrated into systems

Whether it be in the AL sausage filling lines, forming systems or the high vacuum fillers – using the Handtmann inline grinding system always ensures further optimisation of product processing and quality. The sensory attractiveness of the products is a key advantage.

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT