- New

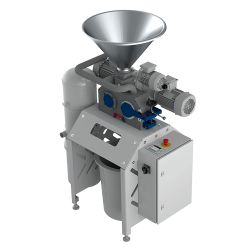

Boston Shearmill Wet Mill/Homogenizer for Particle Size Reduction

The Boston Shearmill (BSM) series of inline wet mills surpasses the capabilities of conventional shear pumps and colloid mills by providing very high throughputs at extreme shear rates.

Description

They meet the toughest hygienic standards and are 3-A compliant.

Particle size reduction is important in the food, dairy, beverage and other industries, and this product is a standout. For processes requiring milling of soft particles to

Wet milling substances with rotor-stator machines provides several advantages. Designed to run 24/7, our wet mills mix, disperse, emulsify, pulverize, macerate, crush, homogenize; reduce solids particles with minimal dust formation; and withstand uneven flow patterns, jolts, and pressure fluctuations.

The Admix Boston Shearmill is routinely used for for tomato paste standardization, salad dressing and mayonnaise processing, pet food production, flavor emulsions, pharmaceutical preps and API blending, polymer blends, and more.

Shearmill Product Features

The BSM 25, 37, and 60 series provides a wide range in capacity, power consumption and tip speed to allow best results for your process!

- Highly modular product series

- Most models are designed for up to three shear heads to be installed

- Each shear head has up to three shear zones, for a total of up to nine shear zones in a single pass

- Wide range of rotor/stator combinations from coarse to ultra-fine

- Special purpose rotors and stators available to provide low shear or extra chopping where required

- Low maintenance design for continuous 24/7 duty

- Meets 3-A standard #36-01

- CIP – easy-to-clean with no crevices, deadlegs, or open threads

- Solid particle/aggregate particle reduction dependent on durometer of particle

108 other products in the same category:

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT