- New

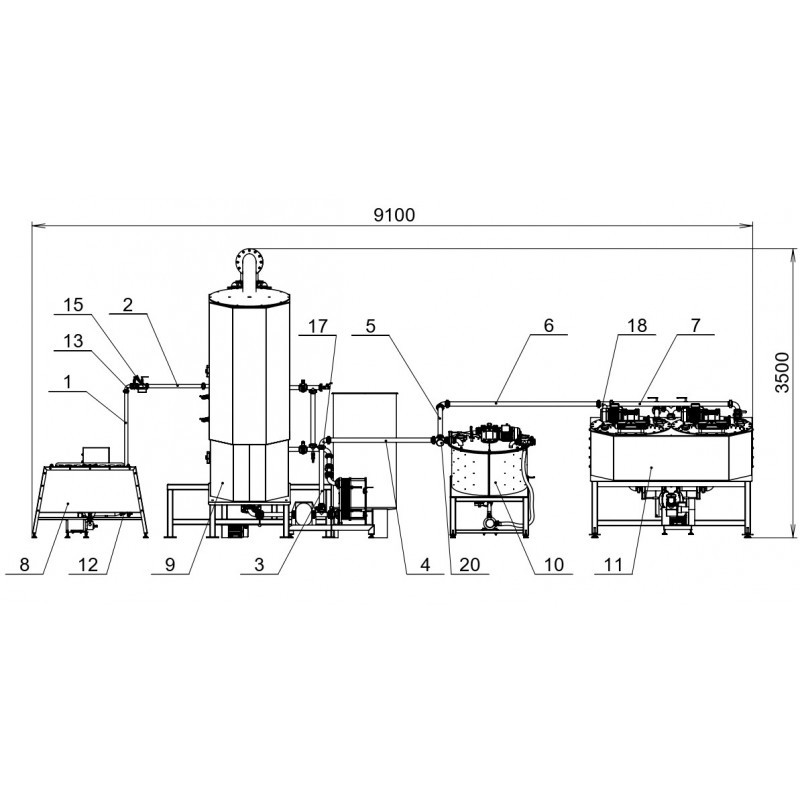

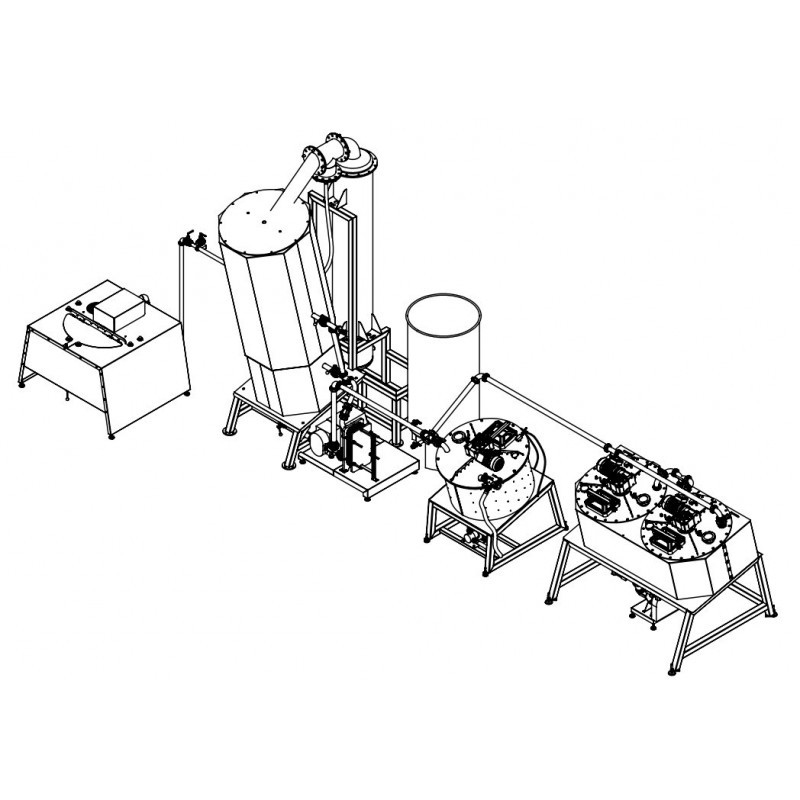

Condensed milk line

This equipment is designed to produce condensed milk in accordance with standards using pre-pasteurized milk. It is available in models with production capacities of up to 100 and 285 kg/h.

Description

This equipment complex for the production of condensed milk is designed for using pre-pasteurized milk, in accordance with GOST standards. It is available in models with production capacities of up to 100 and 285 kg/h, and can also be customized to suit specific production requirements upon request.

The line consists of:

- Electric cooking kettle for dissolving sugar and cooking the syrup

- Vacuum evaporator for boiling, thickening pasteurized milk

- Vacuum crystallizer-cooler

- Double-frame unit for thermal processing of various products

The technical parameters given below are the real technical parameters of the produced lines.

Electric cooking kettle for dissolving sugar and cooking the syrup

- The machine designed to have a production capacity of up to 285 kg/h and has the following technical parameters:

A volume of 300 liters

An installed heating power of 19.5 kW

An installed mixing device power of 0.55 kW The atmospheric working tank features a conical bottom and is equipped with a built-in electric heating system. The heating system uses thermal oil that passes through a heating "jacket" (duplicator) and is stirred by a frame anchor agitator. Ingredients can be loaded through a sectional opening upper hatch that is equipped with a safety grate. Additionally, the heating system is equipped with a safety thermostat for adjusting the temperature as needed.

- The machine designed to have a production capacity of 70-100 kg/h and has the following technical parameters:

A volume of 100 liters

An installed mixing device power of 0.25 kW The installation does not come with a heating system with a "duplicator", but the heat carrier can reach up to 0.5 bar. The syrup preparation station is an atmospheric cooker with a heating "jacket" (duplicator) that is mounted on adjustable legs (100mm), equipped with thermal insulation, an electric frame stirrer, and a bottom valve that prevents dead zones when sugar is dissolved. Additionally, the installation features an external decorative casing made of polished stainless steel. The unit can be equipped with a forced circulation circuit that includes a stainless steel flow filter.

To prepare the syrup, granulated sugar is mixed with hot water at a temperature of 60-70 °C, and the mixture is brought to a boil. It is recommended to prepare sugar syrups with a concentration of 65-70% to ensure optimal boiling point of around 105 °C. Higher concentrations of sugar can negatively affect the thickening process and may not mix well with milk due to the high viscosity. After preparation, it is recommended that the syrup is filtered through a stainless steel flow filter to remove large mechanical impurities or undissolved sugar. The sugar syrup should be added to the vacuum evaporator at the end of the milk thickening process, and boiled in parallel with the milk to achieve the desired condensed milk product.

Vacuum evaporator / vacuum evaporator for boiling, thickening pasteurized milk

Technical parameters of the installation designed with a capacity of up to 285 kg/h:

Volume - 1750 l.

Installed power of the mixing device - 0.75 kW

Heating "jacket" (duplicator) for coolant up to 0.5 bar

Technical parameters of the installation designed with a capacity of up to 70-100 kg/h:

Volume - 500 l.

Installed power of the mixing device - 0.55 kW

Heating "jacket" (duplicator) for coolant up to 0.5 bar

This setup serves the purpose of cooking-concentrating pre-pasteurized normalized milk. It comprises an inclined vacuum reactor that has a heating jacket extending throughout the working vessel's length. Additionally, it includes a thermally insulated bottom and an external decorative casing, along with a frame agitator equipped with electric drive and scrapers made of fluoroplastic.

Vacuum crystallizer-cooler

Technical parameters of the installation designed with a capacity of up to 285 kg/h:

Volume - 350 l.

Installed power of the mixing device - 0.75 kW

Heating "jacket" (duplicator) for coolant up to 0.5 bar

Technical parameters of the installation designed with a capacity of up to 70-100 kg/h:

Volume - 100 l.

Installed power of the mixing device - 0.25 kW

Heating "jacket" (duplicator) for coolant up to 0.5 bar

To create a stable product structure with a uniform particle size, controlled crystallization of condensed milk is necessary. This requires the addition of a seed/fuse, such as dry powdered lactose with a crystal size of 2-3 microns or condensed milk from previous batches that has undergone crystallization with a volume of at least 10%. The vacuum crystallizer unit includes an inclined reactor equipped with a vacuum system, an electric frame stirrer, PTFE scrapers, and a cooling jacket. Note that an ice water source is not included. The unit can be retrofitted with an external circulation circuit with a pump for intensive cooling, as well as a heat exchanger installed in the circulation circuit for faster and more efficient cooling.

To ensure the unit operates correctly, it's crucial to supply ice water with a maximum inlet pressure of 0.5 bar and a temperature of 5-7 degrees to the cooling jacket. Once the crystallization process is complete, the resulting product can be transferred for packaging or additional processing. A separate universal installation is available for this purpose, such as the languishing section for the production of cooked condensed milk.

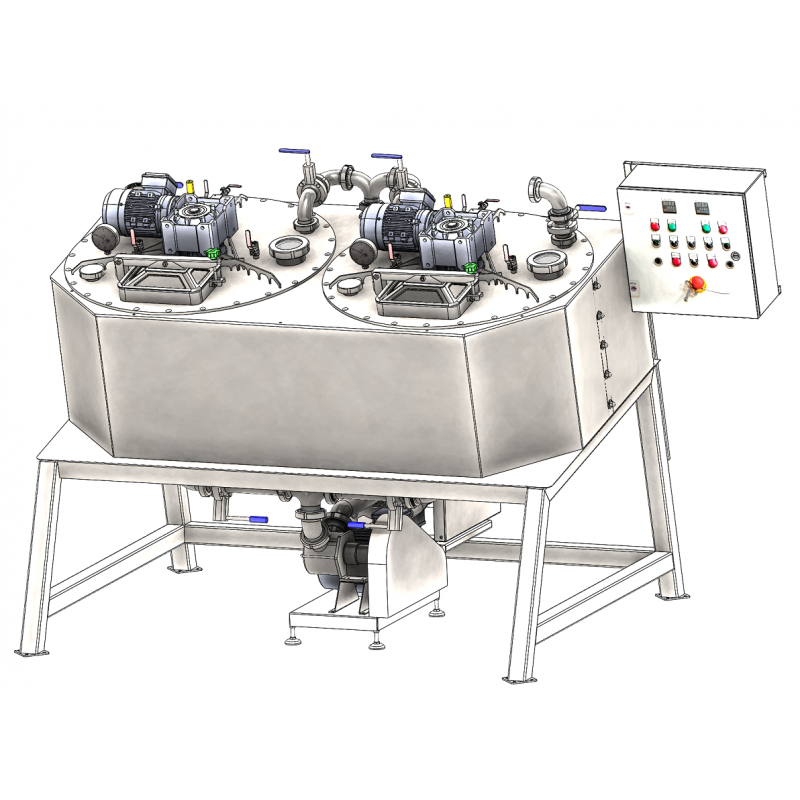

Double-frame plant for thermal processing of various products

The unit is comprised of two inclined reactors mounted on a single support structure, each equipped with a four-layered casing featuring insulation and a heating/cooling jacket suitable for coolant up to 0.5 bar. Optional features such as manholes, viewing windows, and CIP wash heads can be added as per the customer's request. The unit has a volume of 300x2 liters, with an installed power of 0.75x2 kW for the agitator drive. The boilers are constructed of thick stainless steel, designed to withstand up to 0.5 bar of pressure (overpressure) and 0.2 bar of vacuum (residual). The tanks are linked by a system of pipelines that includes manual valves and a product pump, enabling circulation within and between boilers.

- Made from: Stainless steel

- Operational mode: Automatic

44 other products in the same category:

- New

- New

Modular perforated polypropylene shelves for cheese racks / shelves

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT