- New

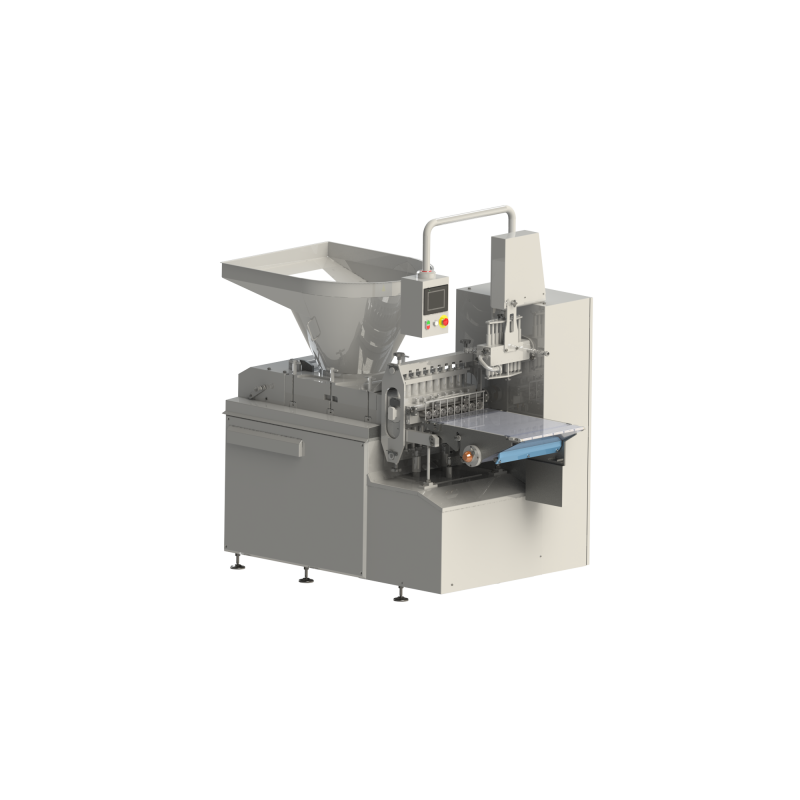

Curd mass dosing equipment GSL.01.B80

Curd mass dosing machine GSL.01.B80 is designed for mass dosing and forming the cheese bar using volumetric dosing method.

Description

Curd mass dosing machine GSL.01.B80 is designed for mass dosing and forming the cheese bar using volumetric dosing method. GSL.01.B80 dosing equipment unit – doses in 8 rows at a time for maximum efficiency and high production capacity. Combined with 8-row refrigeration tunnel GSL.03.A80, distribution system and necessary number of packing units – up to 16,000 bars / hour capacity is reachable.

Also, this is one of the most effective solutions for glazing cheese bars with natural chocolate. As 8 cheeses are dosed at a time, a wider cooling tunnel is used, so that the total length of the line would be shorter.

The dosing equipment performs the following operations:

loading the curd mass into the hopper (using 01.K22 loader);

feeding the curd mass from the hopper to the dosing unit;

dosing of curd mass and formation of “classic” cheeses (can be combined with 04.A filling dosing machine if a filling layer is required inside);

remote control – via control panel – setting of curd mass, filling dose and their adjustment;

transfer of curd cheeses to Enrober 02.B80;

full control of the metering unit from the control panel.

Technical data of the dosing equipment:

weight of cheese bars – from 25 to 50 g;

length of cheese bars – from 45 to 67 mm*;

width of cheese bars – from 20 to 32 mm*;

height of cheese bars – from 20 to 32 mm*;

maximum capacity – up to 16,000 cheese bars per hour;

room temperature – from + 18ºC to + 25ºC, humidity up to 65%;

in order to get more information – CONTACT US!

* Not all minimum or maximum dimensions can be presented at one time.

76 other products in the same category:

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT