- New

Flour Feeding Systems

Complete systems for storing, dosing and handling of flour, granular and/or powder products.

Description

Complete systems for storing, dosing and handling of flour, granular and/or powder products – with following important characteristics:

- raw materials receiving from road tanker, bags, from big-bag and/or from mill (if systems for pasta factories);

- raw materials storage in painted steel, stainless steel and/or reinforced polyester fabric silos;

- automatic dosage of raw materials and/or micro-components, volumetric or weight based;

- “full vacuum” type fluid or mixed phase pneumatic transport, pressure or suction-pressure, complete with cleaning processes, metal presence controls, in-line or batch weighing and compete filtering and dust recovery systems;

- evaluation, designing and supplying of systems for potentially explosive environments, with class 1/D, 2/D and 3D equipment;

- automated processes with management from control panel with PLC and PC supervision system with possible MES interface.

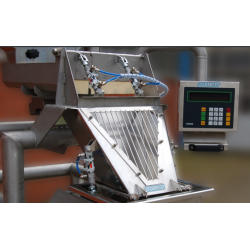

Cleaning system produced using in-line plansifters and metal presence control (first level) in pneumatic conveyor used for feeding pasta lines (systems installed for feeding pasta lines with a capacity up to 12 t/h).

System for weighing raw materials using silos on loading cells, upstream from raw materials dosing and micro-dosing components with weighing system.

Assembly phase for a complex destined to raw material storage (successive closing and insulation phase foreseen).

More specifically for silos, made in AISI 304 stainless steel, or “single block” type (no-bolted joints).

48 other products in the same category:

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT