- New

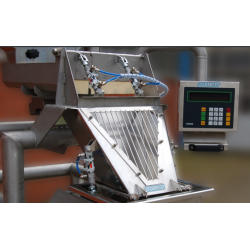

Bacon Belly Slicer Feeding System

Continuous Feed Bacon Slicer

Description

Durable, low-maintenance slicer models for Food Service and Retail bacon.

Variable speed blade turns up to 1500 rpm.

Precision servo-driven feed system.

All components in product handling zone can be disassembled for sanitation and washdown without any tools.

Blade housing safety feature prevents opening until the blade has stopped turning.

PanelView controls for user-friendly interface.

Built in conformity with AMI sanitary equipment design principles. USDA accepted and CE approved.

Description

Continuous Feed Bacon Slicer

Durable, low-maintenance slicer models for Food Service and Retail bacon.

Variable speed blade turns up to 1500 rpm.

Precision servo-driven feed system.

All components in product handling zone can be disassembled for sanitation and washdown without any tools.

Blade housing safety feature prevents opening until the blade has stopped turning.

PanelView controls for user-friendly interface.

Built in conformity with AMI sanitary equipment design principles. USDA accepted and CE approved.

Cozzini takes bacon slicing to a whole new level with the PrimeSlice 827C. Designed with the needs of a Food Service and Retail bacon production lines in mind, this slicer addresses product feeding, operator controls, safety and sanitation. Plastic pinch rollers and a cantilevered design jump conveyor with a sanitary seamless belt feed product to the slicer blade. The blade, powered by a 5 hp stainless steel motor, is fully guarded for operator safety.

Disassembly for sanitation, washdown inspection is easy, since all the components that come in contact with product can be removed without tools. The slicer comes standard with stainless steel bearings, polyurethane timing belt drives and a stainless steel servo motor with IP69K washdown rating for fast and thorough cleaning.

Additional options include wash-in-place spray systems for both the knife housing and drive housing, which allow the operator to wash the blade from both sides while it runs, without needing to open the blade housing.

An optional weighing system allows each slice to be weighed in real time, eliminating the need to stop during slicing to estimate the needed slice count to attain the target weight. Additional features include digital controls for slice thickness, count and net weight.

With online diagnostics, maintenance schedules and upgrades for Ethernet and SCADA, makes this the ultimate bacon slicer.

48 other products in the same category:

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT