- New

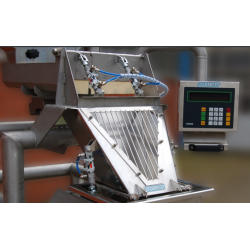

Distribution and feeding system LOMATIC

The new modular feeding and distribution system designed for all speed ranges.

Description

Up to 160 rows per minute can be processed in continuous operation. The fully automatic system is primarily used in the confectionery industry (for chocolate tablets and chocolate bars) following their moulding or enrobing machines as well as in the biscuit and wafer industry for controlled row by row feeding to packaging machines.

Special advantages of our feeding system:

Highly efficient, fully automatic system for feeding wrapping machines, specially designed for the chocolate industry

Full row and shape contents can be taken over, singled and discharged in rows

High outputs due to servo-driven belts and overhead chains

Packing these products:

Chocolate

Non-food

Food

Dry baked goods

Customer benefits: our success key factors with feeding systems

Most modern, modular system in hygienic design

Customized machine concept

Belt tracking regulation on all conveyors over 500mm wide ensures the run out accuracy of the Transport belt and increases its durability

Identical turning rollers, roll scrapers and belt scrapers on the entire line

All lateral reels are executed as rolling belt edge reverse to guarantee a particularly quiet operation

All articles in contact with products in food-safe design

Without pneumatic components. The entire drives are equipped with efficient AC-servo motors

Continuous or not continuous take-over of products rows or complete mould contents, according to the application.

Products are transported on the main conveyor in one level and are discharged to the cross conveyor below:

> Minimum row or block Offset

> Consistent control of product flow on main conveyor

> Trouble shooting during normal operation

Modular design for scalable systems at any time (up- & down- scaling)

Minimal amount of maintenance. Tool-free exchange of belts on entire conveyors within 5 minutes maximum

Direct refeed by means of buffer belt or integration of third party storage equipment

Cross belt can discharge in both directions (a mirrored station is not necessary)

48 other products in the same category:

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT