- New

Cross feeding stations

Contract price

Transverse discharge of product rows from a product layer and continuous feed to a packaging machine

UPC:

EAN13:

Description

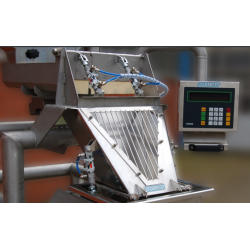

Cross feeding stations

- Transverse discharge of product rows from a product layer and continuous feed to a packaging machine

- Depending on the station's design a limited containment of the products may be possible; this makes it easier to ensure continuous operation of the packaging machine

- Product rows which cannot be included are guided via a bypass either to the next station, an overflow belt or a PFR

- Stations can either be "direct" or "indirect"

- Direct: The products are transferred directly onto the transverse discharge belt. The row is then guided via the lateral branch to the packaging line. These stations can be optionally fitted with additional transverse discharge belts for storage purposes; rows are collected via a deflector and guided towards the packaging branch.

- Indirect: The product row is first transferred to a dead plate; the dead plate empties the rows onto the transverse discharge belt as soon as the previous row has been discharged.

- Hygienic design: All functions like transverse discharge belts, storage belts or dead plate are above the main belt and therefore provide optimal access to detect any soiling and allow for cleaning.

- Optimal accessibility for maintenance and cleaning due to

- easy pushing back of dead plate and transverse discharge belt

- transverse discharge belt having cantilever design

- minimal casing and large ground clearance

- easy handling.

| Row count | up to 50 rows / min |

- Integrated breakage ejection (fast unloading) as a space-saving solution for the first station in the line

48 other products in the same category:

- New

Distribution and feeding system LOMATIC

- New

Refrigerated meat mincer with automatic feeding C/E901 R

- New

TOSS linear weighing unit type 238

- New

Brabender FlexWall®Classic Loss-in-Weight Feeder

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT