- New

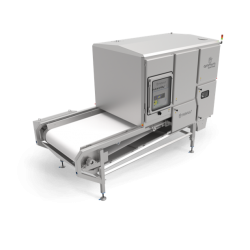

RS rotary sifter

The RS rotary sifter is used in many industries as a pre-sifter and a final sifter, under silos and before vessels, or in feeding stations.

Description

The ideal system for preparing bulk material is a rotary sifter from Zeppelin Systems. It can be used as a pre-sifter before silos, a final sifter underneath feeding stations and vessels, or as an inline sifter for pressure-sealed operation at up to 0.8 bar overpressure or negative pressure in pneumatic conveying lines.

The rotary sifter has been successfully used in the food industry for decades; as such, all parts that come into contact with the processed material are designed to ensure food quality and compliance with EHEDG guidelines and BG regulations, and are also very easy to clean. The design of the sifter drum also means that it can be easily inspected, cleaned, and if necessary replaced, via the inspection openings on the side of the sifter. The drum may be made from polyester or VA stainless steel. A slotted sifter drum is recommended for use in heavy-duty applications. Additional sealing rings maintain a seal between the sifter basket and product chamber.

The sifter is used in the plastics and carbon black industry in a very similar way as in the food industry: For the removal of foreign bodies and verification of grain size. The mesh size of the sifter drum can be customized from 0.25 mm to 8 mm. The main benefit of this is in the continuous checking of raw material – in other words, the separation of coarse material and the loosening or breaking up of product lumps for better use of raw materials. The sifter also protects all sensitive downstream processing machines.

In general, rotary sifters are compact, robust, and low-vibration, and are specifically designed to ensure outstanding efficiency and a long service life, as can be seen in features including the double bearings on both the conveying screw and beating bars. The sifter can be fitted with automatic sifter drum monitoring (Screen-D-Tect) as an option. This continuously monitors the condition of the special screening mesh during operation. Any screening material tear or sifter drum wear is detected and alerted, minimizing the risk of a production breakdown or defective batches. A facility to automatically clean out the sifter drum is also possible. The rotary sifter is, of course, also available in a version that is suitable for use in Zone 21 or 22 areas, in accordance with ATEX Directive 2014/34/EU.

Characteristics

- Wide variety of sifter drum types (plastic sifter, plastic sifter for Screen-D-Tect (SDT), perforated plate, slotted sifter)

- Sifter drum variants are available in a wide range of mesh sizes, slot widths, perforation diameters (round/square perforations)

- For integration into pneumatic pressure and/or vacuum conveying systems

- Small footprint with high performance

- Sealing gas unit as standard

- Food safety: Plastics, seals approved for use with foodstuffs, H1-compliant bearing lubricants

- Coarse material fill-level monitoring

- Durable and low-maintenance

- Easy to replace sifter drum without tools

- Machine maintenance port

- Pressure range between -0.4 bar and 0.8 bar (g)

- Mechanical design pressure up to 0.8 bar (g)

- Mechanical temperature resistance from -20 to +80°C

- Declaration of incorporation or declaration of conformity in accordance with the Machinery Directive, EC type examination certificate and declaration of ATEX conformity available

Equipment configurations, options and accessories:

- Sifter drum blow-off system to remove bulk material deposits on the sifter drum

- Screen-D-Tect for the automatic detection of breakages

- Coarse and fine material output

- Frame

- Bypass system

- Double flap

- Material inlet/injection nozzle

73 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT