- New

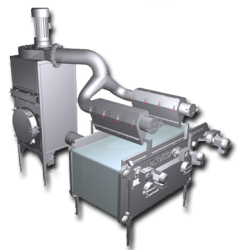

HILLER COMPACT UNIT DecaSmart DP31

The newly developed DecaSmart compact system series is ready for use immediately for your separation task. HILLER compact units for dewatering, can be put to work on your separation task straight away.

Description

In order to be able to offer an optimal solution for different throughput volumes, a DecaSmart of the decanter size DP31 is offered in addition to the current HILLER DecaSmart DP45N. The most significant advantages of the new, compact decanter series, among others, the quick availability for the operator, the simple plug and play integration into the running operation, as well as the attractive price with low operating costs. All process-relevant units are optimally matched to each other and are controlled and monitored via the integrated, userfriendly HILLER switchgear.

The installed units are interlocked via switchboard.

Fully automatic operation is ensured by our centrifuge control unit SEE-Control pro, also integrated in the switchboard. HILLER compact units are a high-performance, economical and technically highquality solution for your separation task.

HILLER compact units provide a powerful, economical and technically high-quality solution for your separation task.

HILLER systems have always stood for high operational reliability and long service and maintenance intervals. All units and measuring instruments are obtained exclusively from reputable companies with a focus on a long lifetime and maximum operational safety.

ADVANTAGES

no planning costs

one contact person

defined, standardised interfaces

easy plug and play integration into the process

low acquisition costs

low space requirement

rapid availability and operational readiness

fast maintenance and spare parts supply

simple handling

mobile applicable

DESIGN DATA:

■ throughput rate: up to 5m³/h

■ automatic polymer station for liquid polymers

■ outer dimensions: 5550mm x 2150mm x 2100mm

■ transport weight: approx. 5000kg

■ connections:

■ sludge (suction connection): flange DN80 PN16

■ centrate (unpressurised): flange DN100 PN16

■ water connection: flange DN40 PN16

■ flushing water outlet: flange DN100 PN16

■ solids discharge via trough conveyor

■ adaptors and plugs available for all standard connections

■ electrical connections:

■ 400V 50Hz

■ 32A

■ approx. 20kW

33 other products in the same category:

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT