- New

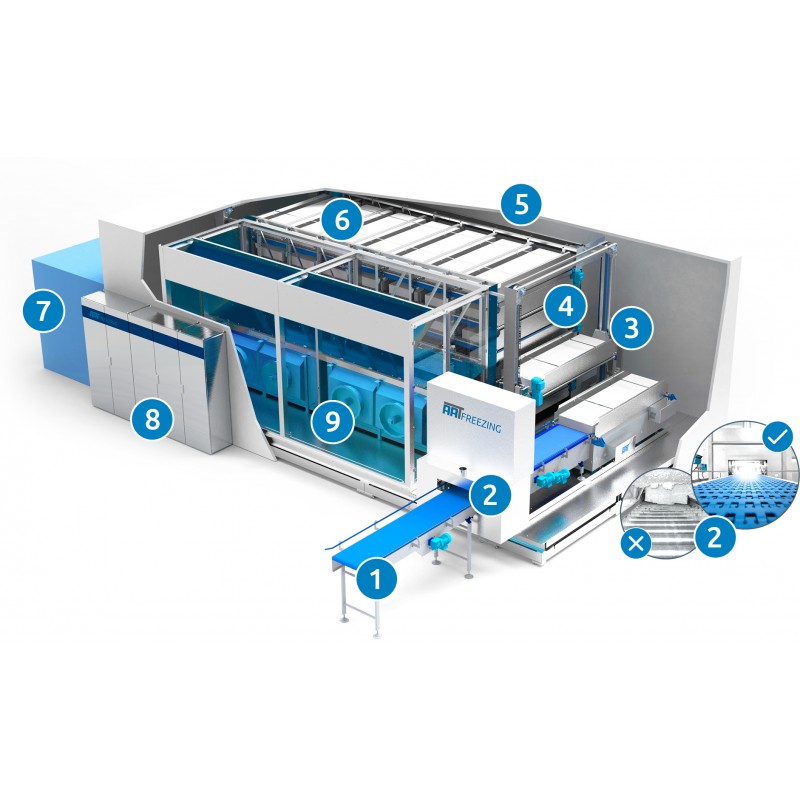

Small BoxFreezer

Contract price

AAT-FREEZING systems are among the most advanced freezing systems on the market.

UPC:

EAN13:

Description

Advantages of Small AAT BoxFreezer:

- The system can be easily extended or relocated due its modular structure.

- Low assembly costs on site – the system is delivered in finished modules.

- The Small BoxFreezer comes with an insulated foundation system – only a normal hall foundation is needed on site.

- The Small BoxFreezer is available with a matching refrigeration system. The customer only needs the electrical power supply for the system.

- Little to no ice formation in the Small BoxFreezer due to dehumidifying at the air locks.

- Due to the Airflow Shelf principle, the products in the Small BoxFreezer are ideally circulated with air.

- The Small BoxFreezer can be used on a wide range of products – cartons, crates, ice cream containers, dairy products, convenience food and many other types of product packaging.

- An ingenious loading and unloading system, which works without pushing out the products, does not cause damage to the cartons, boxes or other product packaging. As a result, there is no dust, wear or dirt due to damage to the products.

Thoroughly designed down to the last detail

In contrast to comparable freezing plants, such as spiral freezers or cold rooms, products with different freezing times can be cooled with the Small BoxFreezer. This is just one of the many innovations that our Small BoxFreezer has to offer.

- Input and output station:

The input station forms the interface to the other production areas, such as slaughter, cutting or packaging lines. As a seasoned expert in conveyor systems and special machine construction, AAT-FREEZING also offers a broad product portfolio in all of these areas.

- Air locks:

It is possible to install a combined loading and unloading air lock or two separate locks for loading and unloading the system. To avoid ice formation, we use a MUNTERS air dehumidifier in our Small BoxFreezer.

- Loading and unloading conveyor:

The loading and unloading conveyor ensures trouble free loading of the product carriers (airflow shelves). The products are gently placed on the product carrier by the conveyor system.

- Lifting station:

The lifting station moves the products to the prescribed level and ensures optimal filling of the Small BoxFreezer. It also makes it possible to sort products according to freezing times.

- Insulation:

The Small BoxFreezer is completely encased in insulation to ensure efficient freezing and not waste any unnecessary energy.

- Innovative product carriers (Airflow Shelves):

The Airflow Shelves are designed to allow the airflow to pass through, above and below the product. As a result, it is cooled faster and more efficiently.

- Refrigeration system:

The system is available with an efficient refrigeration system, which has been designed specifically for the plant. The Small BoxFreezer can also be connected to an existing refrigeration system.

- Control cabinets:

The system is equipped with high quality electrical components, such as Siemens, SEW, SICK and Pepperl + Fuchs.

- Air coolers:

The air coolers are mounted on the side relative to the direction of flow. This allows for even cooling along the entire system. In addition, this optimises the air flow to the product.

62 other products in the same category:

- New

The MILMEQ® Single Retention Time Tunnel

- New

Refrigerated cabinets GN2/1 ventilated FP70BT

- New

Spiroaertex (packaged and unpackaged food)

- New

Cold Store refrigeration units - Industrial Series

- New

MILMEQ® Multiple Retention Time Tunnel

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT