- New

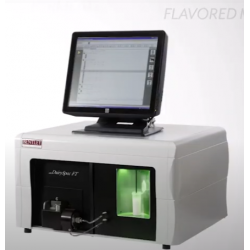

MAP Check 3 - Continuous Gas Analyzer

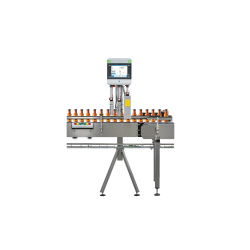

Dansensor® MAP Check 3 continuous gas analyzer is designed to precisely monitor gas content on vertical and horizontal flow packaging machines.

Description

Dansensor® MAP Check 3 continuous gas analyzer is designed to precisely monitor gas content on vertical and horizontal flow packaging machines.

Major gas savings with optional GasSave function or when paired with Dansensor® MAP Mix Provectus® gas mixer

On-line Quality Assurance of every package – more efficiently and with reduced labor and waste costs compared to manual testing

logging and displaying of actual gas consumption with the GasSave function for easy traceability

automatic stopping of the packaging machine if preset limits are exceeded, helping to avoid recalls and repacking

Reduced CO2 levels in the work area to protect employees

This on-line continuous gas analyzer combines gas content analysis with real-time control of package flushing, which for most manufacturers results into a decrease in gas consumption of 20-50%. Reduce gas consumption and production cost in MAP processes.

Benefits

- 5” color touch screen

- Improved data logging capabilities with USB and Ethernet

- Ability to control Dansensor MAP Mix Provectus gas mixer

- Delivered with PC software

- Option: 3-channel multiplexer

- Extended remote monitoring and control options with Modbus TCP

Features

- Enables major gas savings with optional GasSave function or when paired with Dansensor MAP Mix Provectus gas mixer

- Logs and displays actual gas consumption for easy traceability with GasSave function

- Reduces labor and waste costs compared to manual testing

- Avoid recalls/repacking by stopping packaging machines if machine exceed preset limits

- Reduces work area CO2 levels to protect employees

General standard features

Models: Available with LCD display or as “Black Box” without display

Connections: 2 x RS232C, LAN 10/100 Mbit (Modbus TCP), USB, current or voltage output, 24 VDC logic for start/stop of machine and alarms

Power supply: 103 -132 / 207-264 VAC (auto ranging), 47- 63 Hz

Dimensions: 192 x 230 x 375 mm (H x W x D)

Weight: 8.5 - 11.5 kg (depending on model)

GasSave (optional)

Gas media: Any mix of dry O2, CO2, N2 or Ar (0°C to +50°C gas temperature)

Gas inlet pressure: 2 to 10 bar

Pressure drop: Example: 1 bar at 10 bar input pressure

Gas flow: 6 to 500 l/min

Flow measuring: Total and daily consumption

Multiplexer (optional)

Number of inputs: 3 (Channel priority: Selectable, 1-2-3- or 1-2-1-3-)

Accessories (optional)

Protection kit: IP45 protection (NEMA 3S)

Bracket, assembly: Can be combined with MAP Mix Provectus and MAP Check 3 Pressure: 2 brackets, 8 screws

Applications:

On-line monitoring of gas content on a vertical or horizontal packaging machine

Above combined with real-time control of package flushing via an advanced GasSave function

For a variety of food and beverage packages using MAP.

Some examples of our customer applications include:

-Snack Foods - Bakery - Pizza - Meats & Cheese - Fish - Pet Foods - Coffee - Pharmaceutical Packaging - Medical Device

77 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT