- New

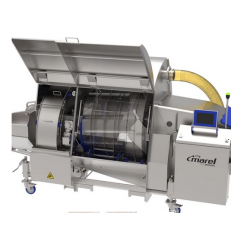

CONVEYORIZED TOPPING APPLICATOR Model WA1000 Series

Capable of evenly applying a variety of toppings to your products, our conveyorized waterfall topping applicator is a simple, easy to use system.

Description

Featuring optional automatic hopper level control, and superior sanitary design, there is no better waterfall applicator available.

PRODUCT:

Rigid and supported products such as: pizza, bread, pies, cakes, or other rigid products

TOPPINGS:

Shredded cheese, IQF ingredients, streusel, nuts,

Vegetables and other ingredients

PRODUCTION RATE:

Up to 100 feet of product per minute

PORTION:

Waterfall application accuracy depends

on size and consistency of product

CONVEYOR:

Cantilevered design

Stainless steel construction

Polyurethane belting

ELECTRICAL:

480 vac., 3 phase 20 amp circuit 60 Hz.

Other voltages optional

Stainless steel control enclosure

CONTROL:

Allen Bradley Touch screen Interface provides user friendly,

intuitive operation, including conveyor speed selection, rate

indication, and system diagnostics

FEATURES:

* USDA Compliant design

* Easy belt removal without tools

* Heavy duty stainless steel frame

* Rake height adjustable from one side

* Adjustable Infeed and Outfeed conveyor ends

* Center Driven Conveyor

* Product Flinger included

* Hopper Level Sensor included

* Hopper Diverter included

* Stainless steel bearing housings

* Sanitary leveling feet with no exposed threads

* Adjustable speed conveyors can accommodate many different production rates and portions

* Easily adapts to an existing topping line.

* Flat belt pizza conveyor

* Cantilevered design for easy belt change and cleaning

* Open, easy to clean, sanitary design, wash down capable

* Continuous smooth welds.

17 other products in the same category:

- New

Continuous drum coating machine for adding spices and flavors AD

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT