- New

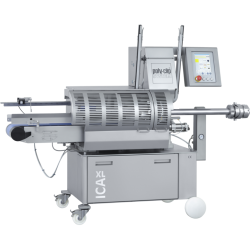

FCA 90

Contract price

The FCA 90 offers unrivalled versatility.

UPC:

EAN13:

New product

Sold By:

view_listView more products of this seller

Description

Top and PCS Exclusive Features

- No one else has it: World's fastest automatic machine for moulded products

- No one else has it: Automatic central lubrication

- Universal use, product servings & shaped products

- Shaped products up to 1.5 m long (300 mm spread)

- Optionally loop on the left or right

Why clip with FCA 90?

The FCA 90 offers unrivalled versatility. It closes collagen casings up to 90 mm, fibrous casings up to 120 mm and plastic casings up to 160 mm (depending on the material thickness). Chubs, cold cuts, ham with only 10 % injected, tumbled pieces of meat, can be reliably processed.

Advantages

- Change of spreading via SAFETY TOUCH, within the standard spreadings as well as to the overspreading, based on the unique PCS motion controller

- Highest productivity, simple operation and self-monitoring processes of the essential functions

- R-ID Clip with high holding force, even up to bacteria-proof clip closure with plastic casings

- Safety casing brake with hand guard; maintaining safety distance to separator when adjusted, operation without casing brake is blocked

- Operating instructions on SAFETY TOUCH. Functions and parameters are explained

- Incorrect settings are avoided by detection of the clip size and die

- Auto-Stop System, clip sensor monitoring end of clip supply on reel

- Uniform pleating and clean sausage tails due to the linear voiding separator

- Highly dynamic, energy-efficient servo drive, infinitely adjustable speed

- Air-free slack filling of moulded products by overspreading, total spreading up to 300 mm

- Simple machine operation with SAFETY TOUCH – shockproof, 10” large and easy to clean

- Operator-friendly with individually assignable manual functions, e.g. inching mode

- Highest productivity; product parameters can be recalled from the SAFETY TOUCH recipe management

- Tool free quick-change system of the punch

- Easy external adjustment of the separator hole

- Manual clip pressure setting

- Electronic hand-wheel for adjustments and setting parameters

- Additional safety by two-handed triggering of first clip

- Product true to the calibre by adjustable conveyor speed; conveyor belt length 1,200 mm

- Simple, ergonomic handling for reloading of casing, without swing-out of the clip head

- Easy to manoeuvre with two lockable wheels

- Low noise level

- Compact design

Maintenance

- Centralized lubrication strip for easy and fast maintenance

- Optimum access for maintenance work

16 other products in the same category:

- New

BDC200 MR two-row, rotary clipping machine

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT