- New

FLOTTWEG BELT PRESSES

High-performance and low maintenance

The belt press is used for dewatering pulp, mash or spent grains silage

Description

Anyone who wants to dewater pomace, mash or spent grains silage uses belt presses. They press the last residue out of the solids cake and are easy to maintain, clean and operate thanks to their easily accessible construction. Flottweg belt presses are robust, durable and powerful - quality made in Germany.

Excellent juice quality is essential when processing fruit or vegetables. In order to conserve the valuable ingredients during processing, the raw material must be processed quickly, reliably and hygienically. The Flottweg belt press masters these challenges effortlessly.

In the production of starch or vegetable milk alternatives, the solids should have as high a dry matter content as possible in order to reduce transport and drying costs. This is also easy for the Flottweg belt press.

The Flottweg belt press is usually part of an overall process. It is often combined with an upstream decanter centrifuge. Depending on the individual process, Flottweg will find the optimum solution and provide all-round support.

The application areas of the Flottweg belt press

How does the Flottweg belt press work?

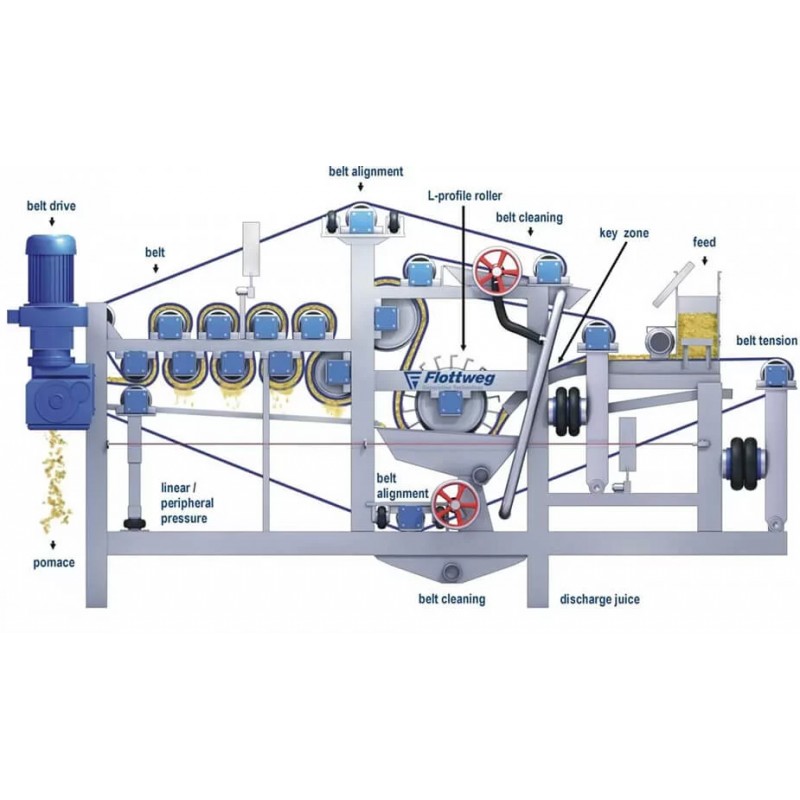

A feed roller distributes the mash continuously and evenly on the lower belt. Due to the static pressure, the mash already produces the first juice. The two filter belts are then brought together. The upper belt presses on the mash cake and ensures gentle juicing and a stable mash product cake.

In the pressing area, an L-profile roller dewaters the mash cake. The L-profile roller ensures fast liquid drainage. A large quantities of juice is extracted here. The L-profile roll is followed by press rolls whose diameter decreases with each roller. These press out the mash even further. At the end of the pressing process, optional line pressure rollers and edge zone press rollers may also be used.

Product features

Power

The press rollers are used to optimally press out the mash. Due to the decreasing roller diameter, the pressure load on the mash cake increases steadily. The increasing pressure load juices the mash optimally and quickly.

As an option, the effectiveness of the belt press can be further increased with line pressure rollers and edge zone press rollers. In a two-stage operation, a yield of up to 90 percent can be achieved.

- Fast juice extraction

- Yield up to over 90 percent

- Gentle pressing process

Safety and security

High-quality materials and the consistent use of stainless steel make the belt press durable and wear-resistant. Various precautions are taken to ensure the safety of the operating personnel.

High process reliability can be achieved thanks to the InGo operator interface. It enables optimum interaction of all process components and sets the highest standards for operational safety, even when in-house components are integrated.

- Increased safety of the operating personnel

- Very good durability and long-life

- High operational and process reliability

Hygiene

During operation, high-pressure nozzles continuously clean both belts after the pomace has been removed. This makes a stable continuous operation of the belt press possible. The washing water used is recycled and reused for belt cleaning. The open construction of the Flottweg belt press facilitates simple and thorough cleaning. The consistent use of stainless steel ensures a high standard of hygiene. In addition, CIP spray pipes can be fitted for further hygiene. These enable fast and effective cleaning with a caustic solution at all important areas.

- Consequent use of stainless steel

- High hygienic standard

- Continuous belt cleaning and additional CIP cleaning possible

Operation

The concise configuration and accessibility of the Flottweg belt press facilitates cleaning, operation and maintenance of the system.

The continuous and reliable operation of the belt press also ensures minimal operating effort. It is controlled from the electrical cabinet. The InGo operating philosophy facilitates the understanding and control of all process parameters. The belts are controlled automatically. It monitors the tension and tracking of the belts and ensures their optimum position.

- Minimum operating costs

- Automatic belt regulation

- Easy cleaning, operation and maintenance

Significantly less maintenance effort

Lyckeby Starch, based in southern Sweden, develops and produces potato starch and fibers for the global food and paper industries. Lyckeby is working proactively to manufacture all its products using sustainable processes.

The company uses a Flottweg belt press for dewatering. This video shows why a belt press is used and which advantages the belt press offers compared to screw presses.

36 other products in the same category:

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT