- New

- New

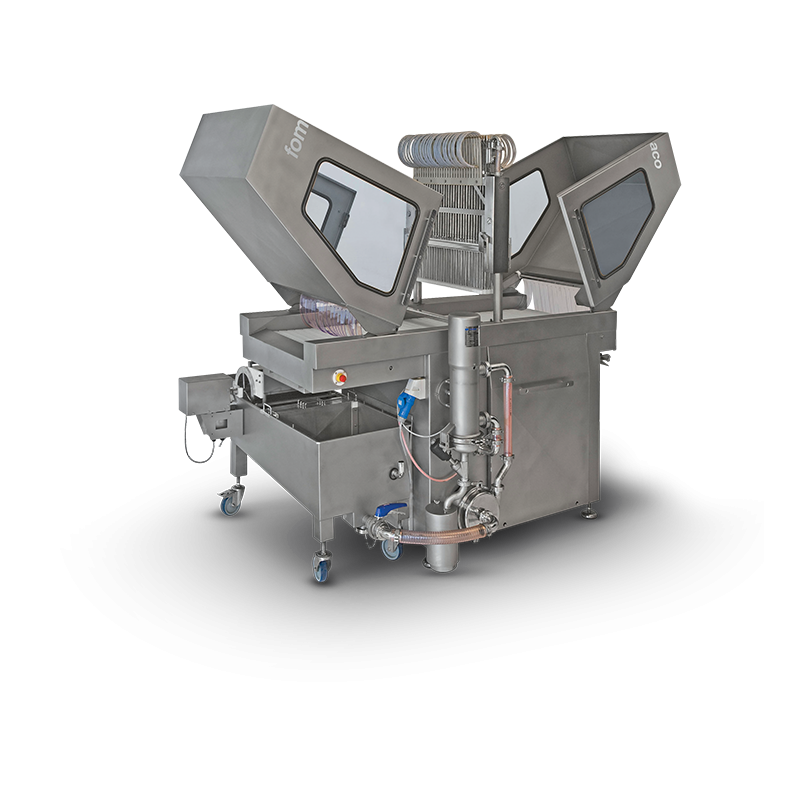

THE FOMACO M2

M2 series is both hygienic in production and easy to clean and offers various sizes of injectors depending on width of the transport systems.

Description

ACCURATE INJECTION

MINIMAL RETURN BRINE

The M2 activates the needle head valves individually, injecting only when the needles are in the product, thus reducing the amount of return brine or marinade considerably.

MAXIMUM CONTROL

The sectionally divided stripper feet follow the contours of the product and prevent the product from moving when the needles are retracted. This also provides a uniform needle pattern and prevents the product from being injected twice – or from not being injected at all.

CONSISTENT BRINE DISTRIBUTION

The high performance centrifugal pump gives a constant brine pressure, ensuring a uniform distribution of brine - regardless of product size and number of needles in the product.

NO BLOCKED NEEDLES

The standard M2 injector comes with an F-80 cartridge type filter. However, you can upgrade to the FM 80 - a fully self-cleaning protein filter uniquely designed to remove all impurities in the brine, preventing the fine needle holes from blocking. This also ensures an even brine distribution, thus improving the product quality overall.

CLEANING MADE EASY

Due to a number of special features the cleaning of the M2 series is both thorough and quick:

- Everything is manufactured in stainless steel and food approved plastic materials.

- All electrical components are fully protected in a separate cabinet with an IP 68 protection so special care is not needed when cleaning the machine.

- Needles can be dismantled and fitted without using tools.

- The conveyor is easily removed without using tools and a separate washing rack is available. The conveyor frame itself has a quick-release system for easy cleaning.

USER FRIENDLY OPERATOR PANEL

Intuitive settings of pump pressure and production speed together with a constant read-out of brine temperature allows for precise and optimum food production.

CONFIGURATION OPTIONS FOR RED MEAT INJECTORS

The M2 series offers various sizes of injectors depending on width of the transport systems (350 mm, 575 mm, and 700 mm). The injectors are available with 26, 44, or 54 needle sockets, mounted with either single, double or quadro needles.

18 other products in the same category:

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT