- New

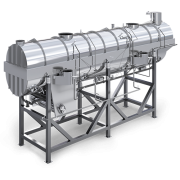

Fluidized-Bed Dryer-Cooler

The fluidized-bed dryer is used to dry, heat or cool powders or granules.

Description

The fluidized-bed dryer is used to dry, heat or cool powders or granules. It is usually used downstream of a spray-dryer to process powder at outfeed, but can also be used as an independent application. Depending on the characteristics of the product to be fluidized (density, grain-size distribution, heat exchange coefficient, etc.), ICF & Welko is able to come up with the best solution to achieve the parameters requested in the end product.

THE PROCESS

1 PRE-PROCESSING OF POWDERS

2 PRE-PROCESSING OF PROCESS AIR

3 HOT AIR GENERATION AND FILTRATION

4 DRYING AND/OR COOLING ON FLUIDIZED POWDER LAYER

5 SEPARATION OF POWDER FROM SPENT PROCESS AIR

6 FINISHED POWDER PROCESSING

ADVANTAGES

The same unit can be successfully used for numerous operations such as drying, heating, cooling, calcination, dust removal and agglomeration, with independent air-flow temperature, humidity and condensation point control and control of fluidizing speed

It operates delicately and efficiently by means of direct contact between the heated air or gas and the product to obtain heat and mass transfer.

The fluidizing process enables the product to flow along the bed without interruption, and to come out of the opposite side.

Can be used to manage products which are sensitive or toxic as a consequence of the heat, or products sensitive to oxygen exposure, or materials with inflammable liquid solvents.

APPLICATIONS

Sugar-based mixes of cocoa, cocoa-milk, coffee or substitutes, coffee milk, tea and chamomile extracts, skimmed and soy milk, non-dairy creamer

Fruit gelatines, aromas, soft drinks, aspartame, maltodextrins, sodium glutamate

Proteins, salt supplements, dietetic products

Custards, confectionery creams, chocolate or vanilla mousse

Baby foods, with precooked flours, with biscuits

Condiments for broth, soups, etc.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT