- Neu

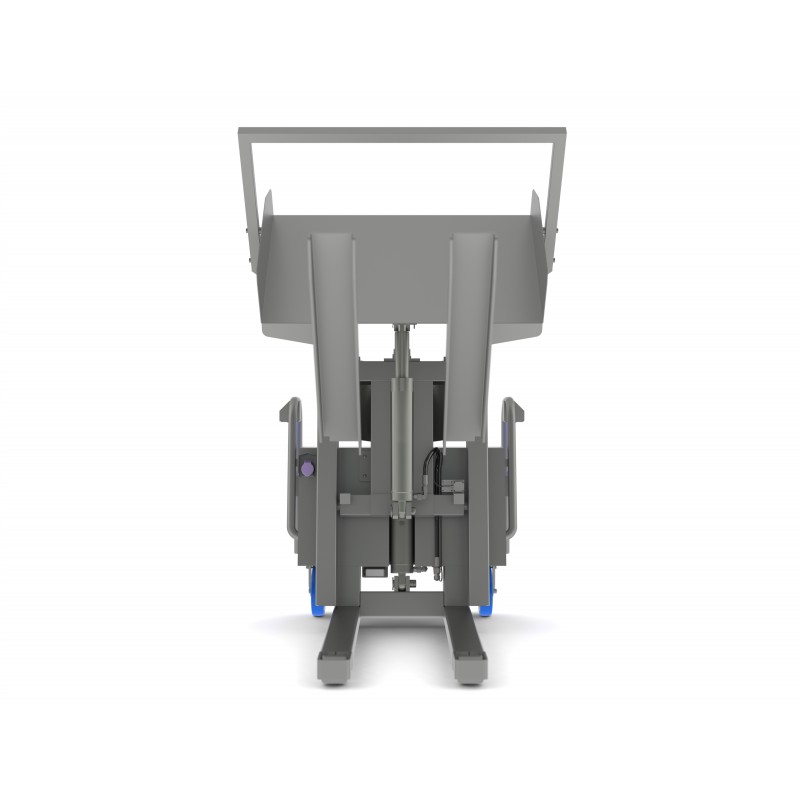

Lifter-tipper Backsaver LT

The Backsaver LT lifting/tipping machine is designed to empty large bins when the Backsaver ST tipper’s dumping height is insufficient.

Beschreibung

The Backsaver LT lifting/tipping machine is designed to empty large bins when the Backsaver ST tipper’s dumping height is insufficient. The LT machine is equipped with a van Oirschot specialty lift-and-tip system that makes it possible to raise a large, heavy bin to a certain height and then tilt it. It’s a compact solution for major tasks. It’s also ideal for use at different locations or for installation at a specific, traffic-heavy location.

Improved process: Backsavers for better production

Backsavers are simple, easy-to-use machines that enhance production and reduce the risk of workplace injury. Independent controls on both sides of the machine are reachable regardless of its actual position, making it ideal whether you work at a table, a process line or an elevated loading platform. It can also be used to fill other machinery, such as grinders, separators, tumblers, cutters, injectors and packers.

Health and enhanced productivity

The LT machine, like a pallet jack, is used to pick up a bin of product (meat, fish, vegetables, etc.) and move it to the location for emptying. The bin is then tipped in a smooth motion until the product starts to come out or even further to the maximum set angle. Because manual lifting, crouching and bending are no longer necessary, the risk of back pain, strain and injury is reduced. Healthy personnel are happier, more efficient and productive, and throughput is maximized.

Powerful rechargeable battery

Backsavers are powered by rechargeable batteries, so they can be used everywhere on the work floor regardless of the power-supply location. The battery is suitable for operation in refrigerated areas and can be plugged in overnight for convenient charging. With a fully charged battery you can handle approximately 40 tons of products.

Operational safety: Gravity-driven lowering action, sound and light alarm

LT, with its two heavy-duty locking swivel casters mounted outside of the frame for maximum stability, can optionally be set to a tipping angle of up to 108 degrees while remaining safe and stable. Like other Backsavers, this machine is driven by a hydraulic cylinder that uses gravity for the lowering action. So, it’s very safe because it significantly reduces the risk that its moving parts might incur bodily injury. For even greater safety, it features an audible backup signal and a flashing LED beacon light that warn others about parts in motion, ensuring extra attention during operation.

Hygiene and food safety: Stainless steel for improved sanitation

Backsavers are developed especially for the food industry. They are safe to operate and suitable for direct contact with food products. These machines are stainless steel for easier cleanups and wash-downs making it possible to use power washers. LT has been engineered, designed and manufactured in the Netherlands since 2007.

Standard Features:

- Twin hydraulic cylinders (1 ea. for lifting and tipping)

- Backup sound alarm

- LED flashing beacon light

- Heavy-duty locking casters

- Powerful rechargeable battery

- Independent controls on each side

- Dead man’s (hold-to-run) buttons (Up/Down)

Available Options:

- Extended-stroke lifting cylinder for dumping at heights of up to 1,410 mm at 100 degrees

- Tapered discharge chute / narrowed spout for improved product flow

- Extended discharge chute: up to 100 mm (4″) without changing the machine’s frame

- Raised discharge chute sides for improved product containment

- Adjustable, swinging or customized retaining bar for various bin sizes

- Different max. tipping angles: 90, 100 and 108 degrees

Markets served:

- Meat processing

- Fruit processing

- Cheese processing

- Mixing/blending

- Vegetable processing

- Other dairy products

- Fish processing

Specifications:

Approx. Dumping Height: 1,260 mm / 49.6" (at 100 deg.)

Max. Bin Height: 1,000 mm / 40"

Tipping Angle: 0-100 deg.

Load Rating: 900 kg / 2,000 lbs

IP Rating:I P56 (limited dust ingress; strong water jets, any direction)

Power Source: 12-volt deep-cycle / semi-traction battery

Approx. Machine Weight: 400 kg / 880 lbs

67 andere Artikel in der gleichen Kategorie:

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

SEMILIFT PLUS Professional Loader for automated craft bakery

- Neu

- Neu

- Neu

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT