- Neu

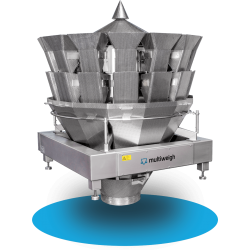

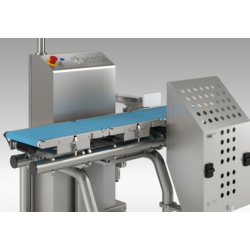

Batch Weigher

The MARELEC Batch Weigher is designed to create fixed-weight batches consisting of numerous products and to fill bags, crates, and cartons.

Beschreibung

Key benefits

- Cost-effective solution

- Up to 10 batches/min

- Connectivity to Matrix software

- Hygienic design

- Ergonomic solution

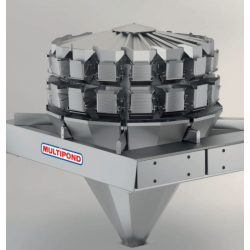

MARELEC Batch Weighers are the perfect solution for creating fixed-weight batches consisting of numerous products. These batches can be dropped into bags, crates, or cartons. Our batch weighers can work with all kinds of poultry parts such as: wings, drums, thighs, giblets, skins, whole leg, leg meat and fillets.

The system indicates when the desired weight has been reached, so an operator is able to replace the bag, crate, or carton with a new one. The MARELEC Batch Weighers use an intelligent algorithm that slows down the feeding speed when the desired weight is close. This guarantees a high-precision batch.

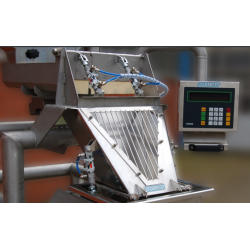

The MARELEC batch weigher consist out of:

- Customized infeed

- MARELEC Weighing Scale with D6 indicator

- MARELEC Batch Weigher software, with flexible speed settings for an optimum balance between capacity and accuracy

- Batching button to indicate a full crate, carton or bag has been replaced with an empty one

Optional:

- Label printing

- Connection to MATRIX software

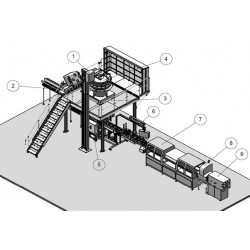

- Batch hopper for extra buffer

- Diverter valve and 2nd batch hopper for increased capacity

Specifications

- Up to 10 batches/min.

- D6-LCD indicator

- Protection: IP67

Cost-effective solution

The batch weigher is a perfect alternative to a grader when only fixed-weight batches are required, without the need to weigh each product individually.

High-speed solution

Capacity depends on indivudual product weight, batch size and options such as extra diverter valves and batch hoppers. Maximum capacity is 10 batches per minute.

Connectivity to Matrix software

All specific batch information can be recorded in the MATRIX software. This information can be used for order management, label printing (optionally), track and trace, etc.

Hygienic design

The open structure allows easy and efficient cleaning after each use. The design of the graders avoids horizontal surfaces. The electronic components are contained in sealed cabinets and completely protected against water infiltration.

Ergonomic solution

Our infeed system is customized to make sure we can fill the crates, cartons, or bags at an ergonomic height. Takeaway conveyors can be provided to minimize time and lifting when replacing full boxes.

75 andere Artikel in der gleichen Kategorie:

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT