- Neu

BRINMIX

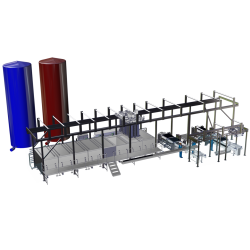

BRINMIX Mixing Technology: optimal Homogeneity, less foam

Beschreibung

The BRINMIX brine preparation systems provide for fast, controlled and efficient preparation of any type of brine or marinade.

The BRINMIX is available in 4 different models for the preparation of brine batches of up to 500, 1000, 1500 and 2000 liters, respectively. Upon request, models for larger-sized batches can be constructed.

Its ergonomic system of adding ingredients by means of a hopper with Venturi suction and high-flow recirculation pump ensures the creation of strong liquid turbulence, resulting in fast dissolution of the brine.

Optionally, the unit can be equipped with a MOLISTICK crushing mill, an indispensable element for obtaining maximum performance of dispersed ingredients such as carrageenans.

Combined with insulated and/or refrigerated accumulation tanks, provides for the creation of complete brine preparation and storage plants with optional touch screen that provides graphic control of brine flow between the tanks and from the tanks to the injector.

Main features

Conical hopper with safety grate to keep foreign bodies out that can be equipped with an optional innovative automatic locking system in the ingredient inlet valve that actuates when the hopper is empty, thereby minimizing the formation of foam.

Cylindrical preparation tank with cover, optional MOLISTICK support and semi-spherical bottom.

Optional insulated cooling jacket with automatic temperature control, connectable to the plant’s cooling circuit or to an optional cooling unit.

Optional system of automatic valves for brine distribution to the injector, additional accumulation tanks or any other point necessary in the production line.

Optional touch screen for control of temperature, mixing times and liquid measure counter for water preparation, with graphic control of brine flow between tanks and to the injector, and integrated maintenance assistant.

Maximum easiness of cleaning and sanitation with hygienic connections in all elements and optional CIP nozzles for cleaning the tanks.

The system can be supplied with a BRINTHERM cooling unit, when required, to cool the water being fed into the Brinmix unit and thereby prevent ice from entering the tank for cooling/maintaining the desired brine temperature. The BRINTHERM unit can also be supplied to lower and maintain brine temperature in the Brinmix unit, or in the accumulation tanks, depending on the configuration of the installation, in order to supply brine at the desired temperature, either to the injector’s filter or to any other point necessary in the production line.

108 andere Artikel in der gleichen Kategorie:

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

- Neu

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT