- Novo

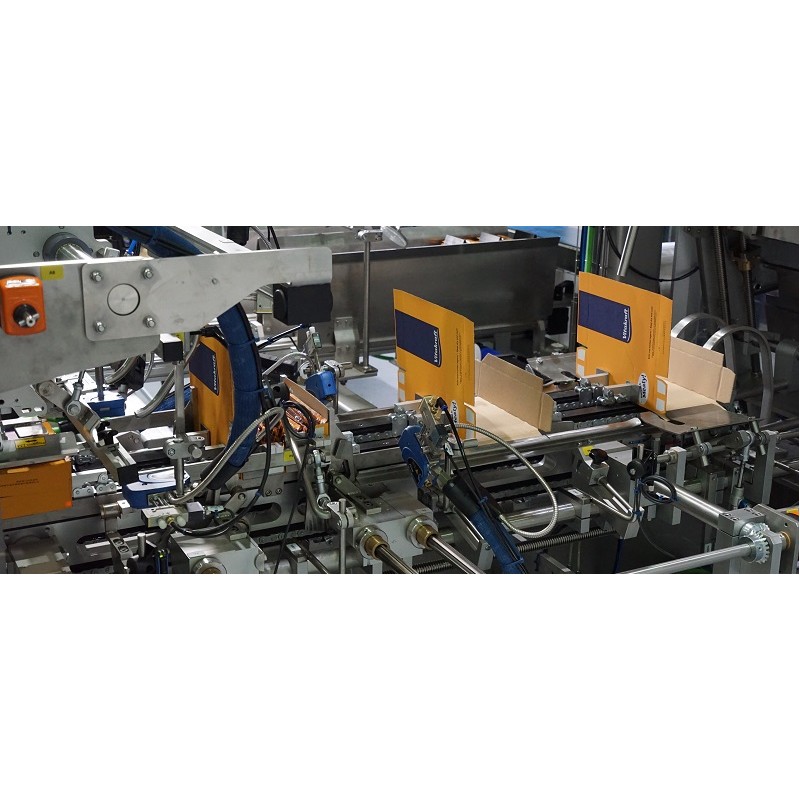

Packer with Delta-Robots FlexLine

A+F machine for picking sticks featuring 4 servo drives for 3D movement

Descrição

- Suction gripper modul ensures reliable and gentle product handling of sticks – Venturi system creates the vacuum

- Reject system for faulty sticks

- Stacking shaft on carriage servocontrolled cycling downwards

- Servocontrolled carriage

- Gantry modul with gripper system for stacking, pneumatic gripping of piled up sticks

- Pneumatic tipping device in gripping system

- Proven A+F ModuLine case line System

Function

Sticks packed in foil as:

- 4 single sticks / layer

- 2 two count packs / layer

- 1 four count pack / layer

- A+F System – Detection of sticks by Sensor Techology

- Rejecting faulty sticks using filler Signal

- Stacking of sticks in Shaft 1 according to pack Formats

- Moving of stacking shaft

- Removal of stacked sticks from shaft and placement in folded wrap around case

- While stacking shaft 1 is in unload position in front of the carton line, stacking shaft 2 is loaded by Flexpicker

- Magazine to hold unfolded case blanks

- Proven A+F ModuLine case linie with folding and sealing stations

- A+F Automation + Fördertechnik GmbH is your partner for turnkey EOL equipment. We also supply control, printing and other systems to complete your production lines

Technical Data

• Sticks packed in foil as: 4 single sticks / layer 2 two count packs / layer 1 four count pack / layer

• Stick sizes: 235mm x 45mm x 10mm (LxWxH); 12g

• Output: 12.000 Sticks / per hour

• Flexpicker Cycle: 1,2 Seconds

• Packing of sticks in wrap around cases

• Servo Drives by Schneider Electric

• Central lubrication possible

• Vacuum pump possible

• PETG panes in aluminium frame

• Pilz security door switches

• Festo pneumatic components

• Schneider Electric Control

• HMI Siemens TP 1200 Comfort

• Individal system design according to customer requirements

A+F guarantees for reliable operation and built-to-last design of all machine components. All bought-in components are sourced from recognized industrial suppliers and meet the highest standards of reliability. Every machine passes a detailed and thorough in-house test run prior to dispatch.

- Quick and reliable format changeover by use of customized format kits and spindle adjustments.

- Low operational cost reached by high-quality design and low servicing requirements.

- Prior to delivery every A+F FlexLine is test runned using original test materials. A final test record is also carried out.

448 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

- Novo

- Novo

PP220 Horizontal Type Pre-Pouch Doypack Packaging Machine

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

LRC-700 Combined Robotic Case Packer & Palletizing System

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

TPM 1000 fully automatic thermoforming packaging machine

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

GF series automatic plastic bottle filling and capping production line

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

Filling and seaming groups for aluminium and tin plate cans

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

Vertical form-fill and seal machine of the “Economy” series

- Novo

- Novo

- Novo

- Novo

- Novo

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

- Novo

- Novo

Seamer for soft drinks, beer and carbonated soft drinks

- Novo

- Novo

MC4TB High-speed wrapper for chocolate tablets and bars

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Novo

- Novo

- Novo

Heavy Duty Double Chambers Vacuum Packaging Machine J-V012W

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

Machine for the production of thermoshrinking bags SA-V TVB

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT