- Novo

Cooling Drum for Sugarless Candy

For all kinds of sugarless candy

Descrição

DETAILS

For all kinds of sugarless candy

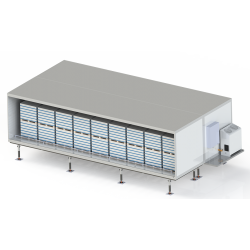

Compact unit, equipped with polished stainless steel drum and integrated lubrication system.

Safe and automatic transfer of hot mass from the cooker is also available.

Weighing and cutting unit to control batch size also available.

Capacity up to 600 Kg/h (1,300 lbs/hr)

RCT.100S

RCT.150S

CATEGORY

Sugar Free

TAGS

Hard candy, Lollipops, Sugarfree

Product Description

All Confitech cookers for hard candy can also produce sugar free sweets.

When sugar free candy is produced on CKU.50, CKU.75 or CKU.120, the hot mass delivered by the cookers must be first cooled down to a suitable temperature to mix flavours and colours before proceeding with tempering and kneading. This is achieved by a special Cooling Wheel, the RCT.100S or RCT.150S featuring a polished stainless steel drum with an automatic lubrication system and water temperature control.

Capacity ranges from 300 to 600 kg/h.

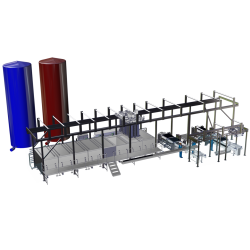

The all stainless steel enhanced version of the RCT.100S or RCT.150S can also be equipped with a weighing and cutting unit. This is fully integrated within the frame of the machine, to meter the product coming off the wheel and deliver batches of pre-set size directly into the kettle that fits with the Mixer for Flavour and Colour ME.70B and the Kneading Machine IM.70

To avoid manual handling of the hot candy mass the ancillary unit SFT.100 can be placed under the discharge point of the cooker to collect the hot product and transfer it into the hopper of the Cooling Wheel without any risk for the operator.

The SFT.100 consisting of a steam heated hopper and a heavy duty transfer pump is a mobile unit fitted on wheels and it can be easily removed and stored apart when standard sugar based candies are produced. That simple and flexible setup is particularly interesting for small or medium facilities where volumes of sugarless products would not justify the installation of a dedicated line, as it allows even small companies to enter the profitable and growing market of sugarless confectionery with a limited investment.

73 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT