- Nuevo

Ketchup systems

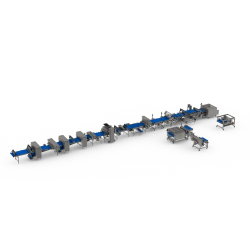

Selo offers two options regarding the production of ketchup and ketchup-like sauces: the batch line and the continuous line.

Descripción

Selo offers two options regarding the production of ketchup and ketchup-like sauces: the batch line and the continuous line. Both lines are well-suited for the production of real ketchup, starch-based ketchup and sauces, like gipsy sauce and ‘Schaschlick’ sauce.

The production of larger amounts of ketchup and other sauces in a batch result in a lower cost price. The machines are easy to clean so the batch machine can be configured and reconfigured for a different product. The continuous line is very suitable for the production of high volumes and ensures flow production: the production process of the ketchup and sauces is continuous and has a low cost price. Apart from production machines for ketchup and sauces, Selo also offers packaging machines for ketchup and other sauces.

OPTIONALLY, THE FOLLOWING COMPONENTS CAN BE INTEGRATED:

- Scraped surface heat exchanger, available with blades that clean the walls. Optimum heat transfer coefficient. Also suitable for sauces with bigger particles. Optimum heat transfer coefficient. Also suitable for sauces with bigger particles.

- Direct steam injection possible for achieving the right temperature at once. Starting and stopping the process without major losses.

- Cooling is possible by means of vacuum cooling, scraped surface heat exchangers or pipe heat exchangers.

- High-pressure homogeniser to create the pressure required for micronising the ketchup and sauces (liquid products).

- High shear homogeniser for production of double emulsions with ‘complex’ structures

BENEFITS OF SELO KETCHUP SYSTEMS:

- Very hygienic design and choice of the right materials

- Flexible capacity, volume number easy to determine

- Limited operator use

- Automated resource input: efficient and hygienic

- Allows for fast recipe change

- Efficient CIP cleaning

- Testing and running test batches in advance is possible in our own Technology Center

110 otros productos en la misma categoría:

- Nuevo

- Nuevo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuevo

- Nuevo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT