- Nuevo

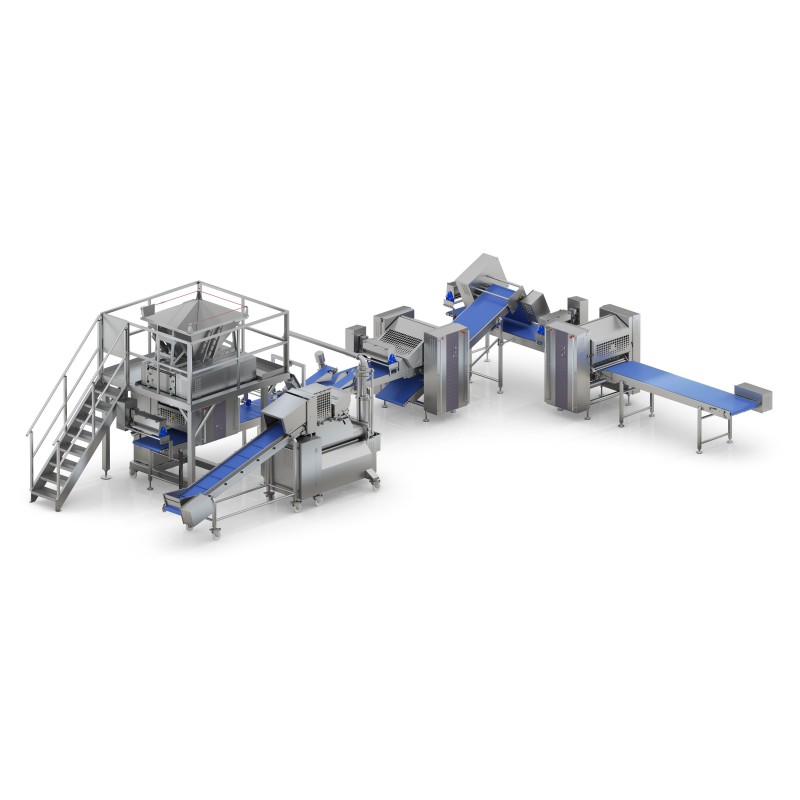

LAMINATOR 700

The LAMINATOR 700 is a true master at laminating puff pastry, croissant, short and Danish dough types in perfect and consistent quality.

Descripción

LAMINATOR 700: THE SHEETING LINE FOR AUTOMATED DOUGH SHEET PRODUCTION

FOR A UNIFORM AND CONTINUOUS DOUGH SHEET

The LAMINATOR 700 is a true master at laminating puff pastry, croissant, short and Danish dough types in perfect and consistent quality. However, it can do far more. The universal version (Section 3) can also handle soft dough types required for rustic baked goods with ease.

For laminated dough types fine and uniform layers are essential; for other dough types the most important thing is to maintain the delicate pore structure. The LAMINATOR 700 guarantees a continuous, uniform high-quality dough sheet. The gentle dough handling in accordance with the FRITSCH SoftProcessing principle guarantees products of outstanding quality. We also paid particular attention to high availability and easy handling.

All the important components of the LAMINATOR 700 can be easily removed without special tools. This ensures swift and easy (re)fitting and quick product changeover. The line can be operated by one person thanks to the central control of all units by touchscreen panel. Every section can be controlled individually and in combination with others. Customised production programmes which can be selected ensure a high degree of automation.

EXPERIENCE THE NEW FEATURES

MAXIMUM EASE OF OPERATION FOR AN OUTSTANDING END PRODUCT QUALITY

Our LAMINATOR 700 can now be configured with even more flexibility thanks to our "Low-Stress" dough sheet former in section 1. The use of a TBP is ideally suited for the gentle shaping of doughs with a TA of 145 to 175. The combination of a LAMINATOR 300 with the dough sheet former DS is particularly recommended for firm doughs that don’t require any proofing times.

In addition to the gentle processing of the dough, high system availability and ease of operation is also of great importance. An automatic, permanent cascade control now makes operation even easier. The tedious calculation of the individual percentage values is no longer needed and due to factor chaining, manual input is no longer necessary for individual drives. When controlling the LAMINATOR 700, it is only necessary to set the power and number of layers that you want to create; all subsequent adjustments are calculated automatically.

The advantages of the new LAMINATOR 700

- New combination option: Now also with the dough sheet former TBP

- Maximum ease of operation thanks to the new cascade control system

Belt speed: Once the guillotine output has been set, the belt speed regulates itself in accordance with the speed of the guillotine.

Adjustment of folding and layer widths: After entering the target and actual values, relevant, dependent values are adjusted automatically.

Weight adjustment: Is done by setting the actual and target weight directly at the calibration head - Display of the components in 3D optics and display of all important values at a glance thanks to the new visualisation

- The new grease pump enables the creation of an even more uniform grease band due to improved flow properties.

TECHNICAL DATA

Table width: 700 mm

Net dough sheet width: max. 600 mm, infinitely adjustable

Belt speed: 0.6 - 6 m/min on exit belt section 3

Dough capacity: 300 - 1,200 kg/h (incl. fat and scrap dough)

Dough block production: up to 1,500 kg/h

Layers: 16 - 144 fat layers

ADVANTAGES

- Continuous dough sheet production at the highest levels of quality

- Gentle working method to maintain the dough structure

- Wide range of applications due to the possibility to process very different types of dough

- Short retooling times and quick product changeovers

- High automation comfort by customised production programmes which can be selected as required

- Quick and easy operation

- Comfortable data backup by USB interface

- Long service life due to robust stainless steel design

- Easy to clean due to hygienic design and good accessibility

OPTIONEN

- Dough infeed belt to the dough sheeter

- Dough pre-portioner for automatic feeding of the dough sheeter

- Infeed table for fat blocks

- Thinner final dough sheet using a second calibrating head

- TBP and dough portioner for automatic feeding in section 3

- Switch cabinet: stainless steel finish

- Block production with guillotine

110 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuevo

- Nuevo

- Nuevo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT