- Nuevo

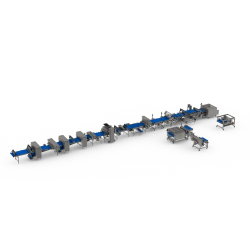

Fully Automatic Kurkure Production Line

Contract price

The fully automatic Kurkure production line is a continuous processing arrangement, which is suitable for frying of Kurkure (Nick-Nack)

UPC:

EAN13:

Nuevo

Vendido por:

view_listVer más productos de este vendedor

Descripción

The fully automatic Kurkure production line is a continuous processing arrangement, which is suitable for frying of Kurkure (Nick-Nack)

Special Features

- Frying Control

Specially engineered multi oil inlets maintain positive oil flow to clear the product infeed area & provide precise control of temperature & rapid adjustment to feed change. - Continuous Filtration

Circulating oil keeps fines in suspension for efficient removal. Every minute 100% of the system oil volume passes through drum filter to remove 100% products particles for the highest oil & product quality. - Oil Quality

Low oil volume and rapid oil turnover assure fresh product with a long shelf life. Optimal level is automatically maintained. - Buffer Hopper

It ensures constant feed to fryer despite any small change in extruder output. - Slurry System

Seasoning is added to the product using nozzles in the zig-zag drum to get mixed with the collates. Specially designed zig-zag drum & controlled slurry application ensures uniform coating.

| Model | FAKPL - 300 | FAKPL - 500 | ||

|---|---|---|---|---|

| Output | 300 Kg/ Hr | 500 Kg/ Hr | ||

| Edible Oil Holding Capacity | 250 Ltrs | 450 Ltrs | ||

| Power Required | 75 HP | 90 HP | ||

| Floor Space | 1500 Sq. Ft. | 2000 Sq. Ft. | ||

| Length Of the Line | 71 ft | 75 ft | ||

| Material of Construction | AISS-304 | AISS-304 |

110 otros productos en la misma categoría:

- Nuevo

FLAT CRISPY BREAD PRODUCTION LINES

- Nuevo

Complete packing lines DAIRY PRODUCTS

- Nuevo

LINE FOR THE PRODUCTION „SMALL BEETLE” MODULDED CURD

- Nuevo

Casing Lines Mod. LB Standard/Economical

- Nuevo

Production Lines & Systems

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

Contract price

- Nuevo

Complete plants for the dairy industry

- Nuevo

Complete packing lines PASTA & READY MEAL

- Nuevo

Production Lines & Systems

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

Contract price

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuevo

VARIOFLEX M 700: the coppact pastry make-up line

- Nuevo

BREAKFAST CEREALS PRODUCTION LINES

- Nuevo

Lines for puree, concentrates.

- Nuevo

Deep-fried Dough Sticks Food Frying Machine

- Nuevo

KAS 01/SA chain linking system + AHL hanging line

- Nuevo

Meat broth extraction and concentration process line

- Nuevo

MDL 800 Multi Decoration Line

- Nuevo

Chocolate Production Station

- Nuevo

GPiCS mozzarella cooker stretcher

- Nuevo

Rotary Koji Making Machine

- Nuevo

Breakfast corn flakes food machine

- Nuevo

DISCONTINUOUS DISTILLATION PLANT

- Nuevo

Drop Depositing Line 275-600mm

- Nuevo

Line for industrial injection of chicken

- Nuevo

Fully automated sandwich line

- Nuevo

LINE FOR THE PRODUCTION FERMENTED BEVERAGES

- Nuevo

Chocolate Moulding Line One-Shot MKCD-F-450

- Nuevo

Integrated Extraction System

- Nuevo

MCC 1500 Multi-Layer Chocolate Moulding Line

- Nuevo

Blini Production Line (BN-24)

- Nuevo

Lines for filling and packing olive

- Nuevo

Depositor One-Shot Line 275-1000mm

- Nuevo

Production Lines & Systems

Artificial Rice Extruding Line / Instant Rice Making Machine

Contract price

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT