- Nuevo

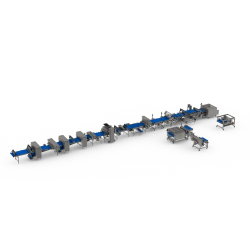

Production Line Pasta Filata

Expert in pasta filata

Descripción

Coagulator

Continuous curd preparation for highest possible yield.

Bassine-System

Curd preparation in a batch process with various levels of automation

Cheese vat

Curd preparation in batch process

Acidification in moulding material

Composed of AFE filling- and mechanisation-system for controlled acidification. This allows long production times without intermediate cleaning.

Acidification and drainage belt

Drainage and acidifcation on continuous belt. Length according to permanence/maturation time

Buffer drainage channel

Maturation auger-channel without whey, transport and pre-cutting of curd

Cooker stretcher WCSH

Hot water cooker-stretcher with paddle system for production of pasta filata cheese with high dry matter (e.g. pizza cheese, kashkaval, etc)

Cooker-stretcher WCSL

Hot water cooker-stretcher with kneading arms for production of pasta filata cheese with low dry matter (fresh mozzarella)

Power moulder

System for moulding and cooling pasta filata cheese in stainless steel moulds

Moulding and pre-cooling carousel

Moulding and pre-cooling system for pasta filata cheese

Dry salt dosing system

Dry salter for automatic dosing and salt mixing

Cooling / Brining vat

Cooling vat with swing-back product transport or brine flume

Brining system

Brining system for specific applications

Mould material

Designed for the optimal acidification process during the draining phase. Draining is performed laterally through grooves or holes

Mould cleaning

Continuous cleaning of the mould material for different levels of contamination

Form fill and seal packaging

Packaging lines incl. continuous product feeding

- Made from: Stainless steel

110 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuevo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT