- Nuevo

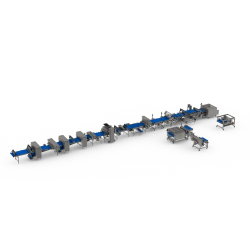

FLAT CRISPY BREAD PRODUCTION LINES

Clextral designs, builds, installs and maintains a wide range of twin-screw extrusion and co-extrusion lines to make crispy flat breads, both plain and filled.

Descripción

Clextral designs, builds, installs and maintains a wide range of twin-screw extrusion and co-extrusion lines to make crispy flat breads, both plain and filled. Clextral lines leverage its unique twin-screw extrusion technology and are highly flexible and scalable. They can be quickly and economically modified to make innovative new products to meet changing market demand.

HOW DOES A CRISPY FLAT BREAD PRODUCTION LINE WORK ?

A mix of selected ingredients is conveyed into the hopper of the feeder, which continuously delivers the dry mix to the extruder where liquid additives are injected. The dough moves through the barrel–screw assembly and mechanical and thermal energies simultaneously cook the paste. Texturing occurs when the cooked dough is pushed (extruded) through the die.

The bands of product are laminated, cut, toasted and packaged.

The processing line for filled products is similar to the crispy flat bread production line, but uses a co-extrusion system. Filled flat bread can be made on the same production equipment as crispy flat bread using the co-extrusion clip-on kit.

CLEXTRAL LINES : GEARED TO OPTIMIZE PRODUCTION

Clextral’s 50 years of experience in extruded and co-extruded crispy flat bread production and its constant innovation means that customers benefit from distinct advantages:flat crispy bread

Production-proven continuous processing techniques and scale-up expertise

Ingredient flexibility to process a large variety of cereal grains and fillings

Expertly crafted dies

A vast array of dimensions and shapes

Processing ability to manage various filling recipes (sweet and savory)

Quick stop, start and changeover

Advanced control systems ensure accurate process control for uniform product

Compact design and reduced floor space

Intensified processing, generating raw material, water and energy savings

Easy cleaning and maintenance procedures

Output from 300 to 1000 kg/h for flat crispy bread slices

Output from 500 to 1100 kg/h for flat crispy bread bars

110 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT