- Novo

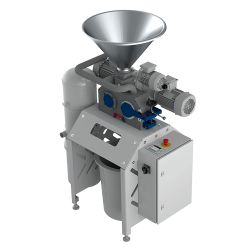

RASPBERRY GRINDER

Unit used to crush the frozen raspberries to the small fractions.

Descrição

Frozen raspberries are passing to the buffer basket. They are pre-crushed by the crushing mill and then transported to the cogged crushing rollers. Rollers and the crushing mill are driven by the separate engines. Unit is equipped with the charge basket with the grille, the inspection hatch to facilitate cleaning. These parts are secured against the accidental openning and drives turning off sensor. Fraction sizes can be set by adjusting the slit between cogged crushing rollers.

- Capacity (2 – 7) t/h depends on working width (400, 500, 600, 700)

- Power supply (Ex. For capacity 3t/h, width 500... Type GR500 )... 5,2 kW, ~3x380VAC, 50 Hz

- Dimensions...( Type GR500 -length / width / height ) 1000 / 1000 / 1800

- Height (Type GR500 - loach / unload ) ..1800 / 950

- Weight Type GR500 280 kG

- Particular dimensions

Example of constructed SET FOR MINCING raspberries which contains of the:

- Screw transporter passing the product into grinder’s charge basket.

- Grinder with the crushing mill

- Vibration sifter with the slotted sieve to screen the light fractions

- Before moving crushed fractions to the optical sorter it is recommended to use the fan separator.

Set of the units for: shredding, grinding of the frozen fruits and vegetables. Unit is equipped with two working sets in the shapes accommodated to their functions. Units are usually connected to the: sifters, batchers, transporters to eliminate direct human contact with the unit. Each unit is also equipped with the control panel, sensors and emergency power off buttons in case of the opening of the cover , basket, and discharge basket. Unit construction enables an easy access to the movable elements for service or cleaning. Direct power through the belt pulley.

108 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT