- Novo

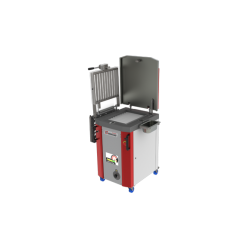

Proofer BIP 72-M

Developed for fully automatic proofing / resting of the dough pieces between rounder and long moulder.

Descrição

This intermediate proofer is suitable for many common dough types, such as wheat and wheat/rye doughs with a low percentage of rye, without the use of any dusting flour.

All frame parts stainless steel or nickel plated.

- Infeed by photocell, capacity 1,200 pcs/h

- Infeed by V-step belt, capacity 1,800 pcs/h, single infeed

- Infeed by V-step belt, capacity 3,600 pcs/h, dual infeed by means of 2-way flipper gate

- Proofer runs intermittently / continuously

- Cast iron hollow bolt chain wheel with shafts, nickel plated

- Pockets round, polyethylene, removable, washable, Ø 190 mm

- Windows Plexiglas

- Frame, turning device, proofer trays and panels stainless steel, parts in contact with dough, Teflon coated

- Chain with chain guides in stainless steel

- Drive SEW gear-box with shear pin protection

- Integrated switch board panel

- PLC control, touch screen for proofer with dual infeed, capacity 3,600 pcs/h

- Stop switch for correct tray position

- Discharge chute with out-feed on last row

- Proofer-head attached to the existing ceiling (by customer).

Performance, maximum benefits and modular options. Principle single infeed by photocell or one V-step belt:

BIP 72-M proofers have been developed for automatic resting/proofing of dough pieces between rounder and moulder. A photocell-controlled infeed system brings the dough pieces one by one into the 1st row of pockets of the proofer.

The proofer runs intermittently (step by step) until 1,200 pcs/hr. At a higher capacity, the proofer will run continuously. When the dough pieces have completed one cycle, the transfer box up in the proofer will bring them to the next pocket.

After the dough pieces have completed all rows, the transfer box brings the them from the last row through a discharge chute or a discharge conveyor (option) to the moulder or final rounder.

Principle dual infeed by one V-step belt with 2-way flipper gate:

BIP 72-M proofers have been developed for automatic resting/proving of dough pieces between rounder and moulder. The “self-thinking” photocell-controlled V-step belt with 2-way flipper gate feeds the dough pieces directly from the rounder into the proofer pockets. The V-step belt feeds them alternatively into the 1st and 2nd row of the proofer.

This system ensures that only 1 dough piece per pocket will be fed, even if the dough pieces do not arrive continuously. The proofer runs continuously and 2% faster than the divider. When the dough pieces have completed one cycle, the transfer box up in the proofer brings them to the next row: the dough pieces from row 1 to row 3 and row 2 to row 4.

After the dough pieces have completed all rows, the transfer box brings them from the last row through a discharge chute or a discharge conveyor (option) to the moulder or final rounder.

- Product quality:

- Teflon coated transfer box for dough transfer between pockets without sticking problems

- Round dough pockets for dough balls results in an optimum proofing

- Variable proofing times

- Daily use:

- Frame made of modular closed tubular profiles out of stainless steel

- All frame parts in stainless steel or nickel plated, no painted parts in dough area

- Stainless steel trays

- Reliable infeed systems

- Plexiglas windows for visual inspection

- Reliable performance thanks to many years of experience

- Cleaning:

- Processing without flour dusting

- Removable and washable synthetic dough pockets

- Ultraviolet light for protection against mould

Hourly capacity per BIP 72-M type:

3 shift proofer design

Infeed photocell, < 1,200 pcs/h

V-step belt, single infeed, < 1,800 pcs/h

V-step belt, dual infeed, < 3,600 pcs/h

Technical details*:

Type infeed photocel:

376 - 416 / 8-2 / 3111 - 1467, 376

392 - 432 / 8-2 / 3111 - 1734, 392

408 - 448 / 8-2 / 3111 - 2001, 408

424 - 464 / 8-2 / 3111 - 2268, 424

564 - 624 / 12-2 / 3111 - 1467, 564

588 - 648 / 12-2 / 3111 - 1734, 588

612 - 672 / 12-2 / 3111 - 2001, 612

636 - 696 / 12-2 / 3111 - 2268, 636

Type V-step belt, single infeed:

360 – 376 - 416 / 8-2 / 3111 - 1467, 360

376 – 392 - 432 / 8-2 / 3111 - 1734, 376

392 – 408 - 448 / 8-2 / 3111 - 2001, 392

408 – 424 - 464 / 8-2 / 3111 - 2268, 408

540 – 564 - 624 / 12-2 / 3111 - 1467, 540

564 – 588 - 648 / 12-2 / 3111 - 1734, 564

588 – 612 - 672 / 12-2 / 3111 - 2001, 588

612 – 636 - 696 / 12-2 / 3111 - 2268, 612

Type V-step belt, dual infeed:

360 – 376 - 416 / 8-2 / 3111 - 1467, 360

376 – 392 - 432 / 8-2 / 3111 - 1734, 376

392 – 408 - 448 / 8-2 / 3111 - 2001, 392

408 – 424 - 464 / 8-2 / 3111 - 2268, 408

540 – 564 - 624 / 12-2 / 3111 - 1467, 540

564 – 588 - 648 / 12-2 / 3111 - 1734, 564

588 – 612 - 672 / 12-2 / 3111 - 2001, 588

612 – 636 - 696 / 12-2 / 3111 - 2268, 612

* net – gross / number of rows-number of legs /

height - head length, net contents (pockets)

Weight range:

200 - 1600 gr,

200 - 1800 gr for mixed dough

Dimensions (lxwxh):

Depending on execution

Connected load:

230/400 V, 50 Hz + earth,

0,5 – 15 KVA

Weight:

Depending on execution

Shipping volume:

Depending on execution

117 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

Electric thermal oil jacketed cooker STM

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT