- Nuovo

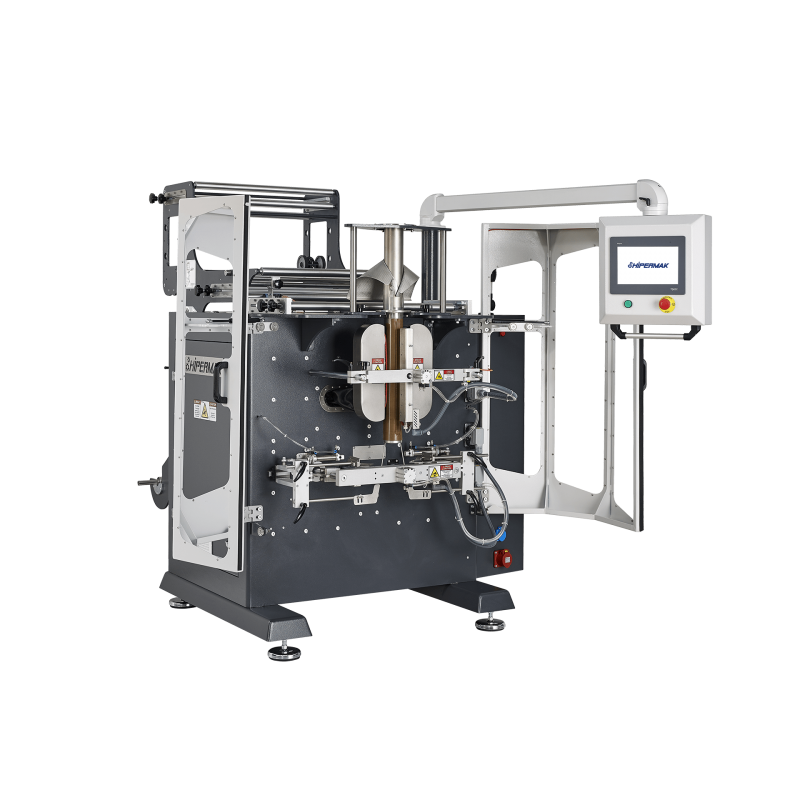

SV5000 Series Vertical Packaging Machines

Contract price

SV5000 Series Vertical Packaging Machines suitable for almost all kind of food and non-food sectors

UPC:

EAN13:

Descrizione

MAXIMUM BAG WIDTH: 300MM

MAXIMUM BAG/MINUTE: 130 PCS

SV5000 Series Vertical Packaging Machines suitable for almost all kind of food and non-food sectors

SV5000 Series Bag Makers allows to pack wide range of goods and bag sizes.

Remote Access, Centralized Lubrication, Easy New Film Adding System, Automatic Centering System are standard functions for Hipermak SV5000 Series Baggers.

You can keep your special tastes and smells of your products with Hipermak VFFS Machines.

Special applications of marketing strategies like Euro Slot, Nitrogen Flushing System , Valve Applicator, easy open are optional functions of Hipermak Packaging Machines.

MAXIMUM BAG/MINUTE: 130 PCS

SV5000 Series Vertical Packaging Machines suitable for almost all kind of food and non-food sectors

SV5000 Series Bag Makers allows to pack wide range of goods and bag sizes.

Remote Access, Centralized Lubrication, Easy New Film Adding System, Automatic Centering System are standard functions for Hipermak SV5000 Series Baggers.

You can keep your special tastes and smells of your products with Hipermak VFFS Machines.

Special applications of marketing strategies like Euro Slot, Nitrogen Flushing System , Valve Applicator, easy open are optional functions of Hipermak Packaging Machines.

General features

- Remote Access

- Centralized Lubrication

- Temperature Control with PID

- Machine Error / Alarm History

- Able to work with or without Photocell

- Constant Film Tension with Balance Arm

- Maximum access for clean and maintenance

- Electorostatic Powdered Painted Body in Multi-Stage

- Dynamic Touch Screen (180° Around Machine – 360° Own Axis)

- Production Control with Bag Counter and Target Bag Quantity

- Automatic Edge Control and Film Centering System with Ultrasonic Sensors

- Highly suitable for all kind of Filling Units (Weigher, Auger, Volumetric)

- Fast, Precise and Stable Packaging Process with Motion Control Servo Technology

| Capacity | 130 Pcs / Minute | Servo Motor | Allen Bradley ( USA ) |

| Bag Dimensions | H: 50mm – 450mm – W: 40mm – 300mm | Touch Screen | Allen Bradley ( USA ) |

| Bobbin Inner Ø | 76 mm | Pneumatic Equip. | Festo ( German ) |

| Bobbin Outer Ø | 400 mm | Electronic Parts | Schneider ( German ) |

| Max. Bobbin Width | 620 mm | Sensor | Sick ( German ) |

| Voltage | 380V/415V – 3 Faz – 50Hz/60 Hz | Bearing | SKF ( Sweden ) |

| Power | 4,5 kW | AC Motor | Bonfiglioli ( Italy ) |

| Voltage Range | ± 5 % | Reductor | Bonfiglioli ( Italy ) |

| Air Requirement | 6 – 8 Bar ( 100 Liter / Min ) | Edge Control | Microsonic ( German ) |

| Fitting Parts | DIN 933/931 A2 AISI304 AA-70 | Color | 7016 / 7035 |

| Weight | 1000 KG | Noise Level | DB < 70 |

optional functions

- Dust Absorber

- Label Applicator

- Valve Applicator

- Anti-static Devices

- Online Oxygen Analyzer

- Gift Card Throw System

- Vacuum Timing Belts System

- Gusseted Bag Forming System

- Nitrogen Gas Flushing System

- Hole punch & Euro hole devices

- Sealing Jaw System for PE, LDPE

- Programmable Centralized Lubrication

- Advertisement Stripe / Promotion Band System

448 altri prodotti della stessa categoria:

- Nuovo

The BEHN + BATES pneumatic packer

- Nuovo

IMW-332 Wrap-around case packing machine

- Nuovo

Loading Units with Triaflex Delta Robots

- Nuovo

Storage And Handling Of Pasta Short Goods

- Nuovo

Automatic Tray Sealer STL

- Nuovo

Machine for storing backing strips in cartons Type 442

- Nuovo

Traysealer M1 - the Flexible Compact option

- Nuovo

WRAP AROUND CARTONER RC-1000

- Nuovo

Semi-automatic Tray Sealers MTS/MTP

- Nuovo

Filling & Stuffing machines

Vertical form-fill and seal machine of the “Economy” series

Contract price

- Nuovo

CS 452 Hot Melt and 456 Pressure Tape Case Sealer

- Nuovo

A pouch counter and boxing unit

- Nuovo

Case packaging system SERVOKART C300

- Nuovo

- Nuovo

Bagging and filling machine – VLRB

- Nuovo

Wraparound Packer SOMIC 424 W3

- Nuovo

Industrial vacuum packer AK-RAMON VP-700 TB 100

- Nuovo

Converger SERVOFEED PF410

- Nuovo

Filling & Stuffing machines

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

Contract price

- Nuovo

Packaging & Sealing equipment

Seamer for soft drinks, beer and carbonated soft drinks

Contract price

- Nuovo

Traysealer A4max - The Primary Class

- Nuovo

American Case-Packers – Top Load

- Nuovo

Packing Line for Freezing Frames

- Nuovo

MC1 The most versatile wrapping machine

- Nuovo

DSU – BUTTER CASE PACKER

- Nuovo

Filling & Stuffing machines

Filling and seaming groups for aluminium and tin plate cans

Contract price

- Nuovo

Compact, automatic traysealers

- Nuovo

TRM-369 FP High speed flow wrapping machine

- Nuovo

SAB 150 fully automatic BLOCK packaging machine

- Nuovo

REVO – For demanding tasks

- Nuovo

R700 Twin line for Bakery

- Nuovo

Packaging & Sealing equipment

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

Contract price

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

- Nuovo

HIGH SPEED SERVO TRAY WRAPPER

- Nuovo

Packaging machines - Cooked lats

- Nuovo

Stacking unit SERVOFEED PF200

- Nuovo

Thermoformer RE20 – The compact system

- Nuovo

THE ADAMS The rotating FFS machine for powders & flours

- Nuovo

BM-364 Sleeve wrapping machine

- Nuovo

Vertical form fill sealing

- Nuovo

Wrap Around Tray Packers

- Nuovo

Packaging & Sealing equipment

MC4TB High-speed wrapper for chocolate tablets and bars

Contract price

MC4TB High-speed wrapper for chocolate tablets and bars

- Nuovo

GALAXY stretch film wrapper

- Nuovo

VCPAL series Carton-palletiser

- Nuovo

Tray Packer SOMIC 424 T2

- Nuovo

Automatic Tray Sealer GAMMA FAMILY

- Nuovo

Robots station pancakes packaging

- Nuovo

TRLS-ST compact stacking and bundling equipment

- Nuovo

VI-17 Tray loading machine

- Nuovo

Semi-automatic tray sealer AK-RAMON TS-200

- Nuovo

Mechanical Adjustable Can Packer "No Compressed Air"

- Nuovo

Packaging & Sealing equipment

Machine for the production of thermoshrinking bags SA-V TVB

Contract price

- Nuovo

VFFS TRIANGLE PACK BAGGER VJ25

- Nuovo

VIPER Wraparound Case Packer

- Nuovo

Complete packing lines DAIRY PRODUCTS

- Nuovo

Packaging & Sealing equipment

LRC-700 Combined Robotic Case Packer & Palletizing System

Contract price

LRC-700 Combined Robotic Case Packer & Palletizing System

- Nuovo

MRM 120 - Moistening and Rewinding Machine

- Nuovo

VENTO-c Continuous Cartoner

- Nuovo

Excel 400 Plus Cup Filler

- Nuovo

REEBASIC Tray Sealer Machine

- Nuovo

Wafer fold wrapping machine LCM-W

- Nuovo

Automatic Tray Sealer MAGIC

- Nuovo

Rotary Applicator Type 544/545

- Nuovo

ACCESS SERIES UNSCRAMBLER

- Nuovo

Hand Tray Sealers MLTB/200

- Nuovo

- Nuovo

Packaging & Sealing equipment

PP220 Horizontal Type Pre-Pouch Doypack Packaging Machine

Contract price

- Nuovo

Complete packing lines PASTA & READY MEAL

- Nuovo

CPSL series Side-load case packer

- Nuovo

TFM - THERMOFORMING MACHINE

- Nuovo

Wrap-Around-Packer 3100 s

- Nuovo

Carton erector SERVOKART C200

- Nuovo

Chocolate bar foil wrapping machine LTM-DUO

- Nuovo

Cube Sugar Factories - R 925

- Nuovo

SI-60 – Spout Inserting machine

- Nuovo

SOLANO Top Load Case Packer

- Nuovo

Evolution SoniXs MS-6 with Roller Conveyor MS-6 Base

- Nuovo

REEFLOW 50 Flow Wrap Machine

- Nuovo

EMF - MULTIPLE WRAPPING MACHINE

- Nuovo

Bagging and filling machine – VBA

- Nuovo

Manual tray sealer AK-RAMON TS-150

- Nuovo

EWF AUTOMATIC PACKAGING DISTRIBUTOR

- Nuovo

- Nuovo

Carton erector SERVOKART C100

- Nuovo

ZeroZero Electronic wrapper

- Nuovo

VFFS STICK PACK BAGGER VL80

- Nuovo

Jelly and Chocolate Ball Wrapping Machine MCJP

- Nuovo

DIBIFLOW 300 flowpack packaging system

- Nuovo

Filling & Stuffing machines

GF series automatic plastic bottle filling and capping production line

Contract price

- Nuovo

SP-10 JUSPER Introduction

- Nuovo

UNPACKING - PACKING MACHINES

- Nuovo

SWF VL 480 Vertical Lidder

- Nuovo

FS 37 Form, fill and seal lines

- Nuovo

Vacuum machine easyPACK-mk3

- Nuovo

Handsealing Device HA 75/95

- Nuovo

TFS 300 hygienic design thermoformer

- Nuovo

FSL 48 Form, fill and seal lines

- Nuovo

Vacuum packer table top AK-RAMON VP-280

- Nuovo

Stackers GSS and GSSB Servo Stackers

- Nuovo

Packaging & Sealing equipment

TPM 1000 fully automatic thermoforming packaging machine

Contract price

TPM 1000 fully automatic thermoforming packaging machine

- Nuovo

UNIQUE BF EV flowpack packaging system

- Nuovo

Closing machine SOMIC 424 VM

- Nuovo

STRETCH WRAPPING MACHINE WITH ROTATING PLATFORM

- Nuovo

Sleeving machine SERVOSLEEVE C800

- Nuovo

ST-8A3P Retort Rotary Pouch Packing M/C

- Nuovo

Packaging-machines - Rotary machines

- Nuovo

Automatic Tray Sealer TL 650

- Nuovo

Modular CartonErector MKA

- Nuovo

SBB 800 horizontal flow wrapper

- Nuovo

High-output thermoform packaging machines

- Nuovo

Thermoforming Machine ML-C 2600

- Nuovo

FME 50 (Rotary Form-, Fill- and Seal Machine)

- Nuovo

Electronic Multipack machine with shrink film

- Nuovo

Shrink tunnel Innopack Kisters ST

- Nuovo

OMNIA6 High speed multistyle wrapper

- Nuovo

RV 200 F Vacuum Chamber Machine

- Nuovo

Shrink wrappers SW Series

- Nuovo

SES-4000L-8 (cartridge type)

- Nuovo

ZACMI Multi-Head Vacuum Seamer

- Nuovo

Top-Loader 2100 s BFS/flex

- Nuovo

VI-41SH_300 Shuttle Loader

- Nuovo

RFS 120 - CUP / TUB FILLING MACHINE

- Nuovo

RFS 40 - TUB / CUP FILLING MACHINE

- Nuovo

Packaging & Sealing equipment

Heavy Duty Double Chambers Vacuum Packaging Machine J-V012W

Contract price

- Nuovo

AR6U - PROCESSED CHEESE PACKAGING, CARTONING MACHINE

- Nuovo

SWF BF 400V Bliss Case Former

- Nuovo

MINI form, fill and seal machine

- Nuovo

Packaging machines - Standard conveying

- Nuovo

CPTL series Top-load case packer

- Nuovo

Lines for filling and packing olive

- Nuovo

Combined Packers – Tray+Top

- Nuovo

JazzVac Atom Desktop vacuum packers

- Nuovo

Food Packaging: vacuum chamber machines

- Nuovo

Vaccum packaging machine MEATY MINI

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT