- Nuovo

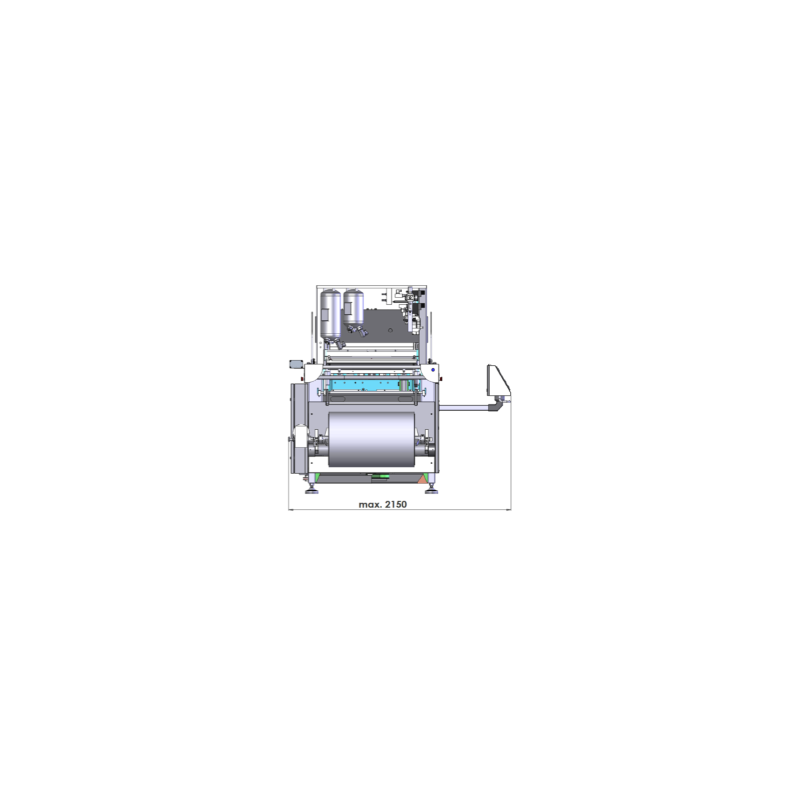

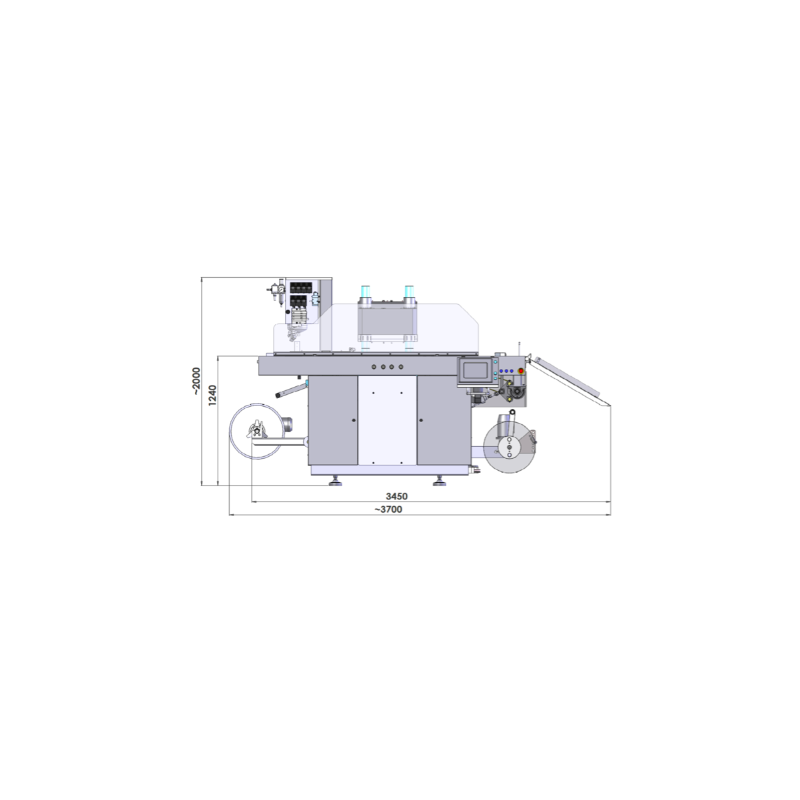

Thermoforming machine TESPRO806

TESPRO806 is fully automatic high-performance thermoforming machine designed for the production of containers from rigid thermoplastic films.

Descrizione

TESPRO806 is fully automatic high-performance thermoforming machine designed for the production of containers from rigid thermoplastic films. Depending on the installed forming mold machine can produce trays, lids, clamshell containers etc. made from various types of polymers such as PS, OPS, PVC and ELM. Maximal thickness of thermoformed film is 800 µm. Forming area dimensions are 790 x 560 mm. depending on applied mold and the film type – maximal forming depth can reach 135 millimeters. TESPRO machine can be equipped with stacker for automatic intercepting of formed containers which enables the full control over the height and distance between the stacks.

Packaging production technology

-

- 1. The material unwound from a roll is fed into the machine forming area. The heating platen is moved up until the knives area reached. The compressed air is injected pressing the material down to the heating platen ensuring its fast and uniform heating.

- 2. As plastic reaches the desired forming temperature, air is exhausted from the mold and forming air pressure is applied through thousands of tiny holes in the heating platen quickly forming the packages.

- 3. After the forming process is completed and the forming air is vented, the cutting dies penetrate the sheet, leaving just enough material to keep the packages connected to the web.

- 4. Then thermoforming machine opens and formed packages are removed by air leaving the mold. In some cases, the mechanical ejector is applied.

- 5. The formed packages, still attached to their web, are transported to the edge of the table and self – detached there.

| TESPRO 806 | ||

| Maximum forming area | mm | 790 x 560 |

| Maximum depth of draw | mm | 135 |

| Material thickness range | mm | 0,2 ÷ 0,8 |

| Maximum sheet width | mm | 820 |

| Maximum cutting lenght | mm | 11.000 |

| Maximum cycles per minute | cykl/min | 35 |

| Minimum air pressure | bar | 6 |

| Air consumption | m³/min | 1 |

| Supply voltage | V | 230/400 |

| Installed power | kW | 35 |

| Dimensions | mm | 3600 x 1520 x 1960 |

| Weight | kg | ~3660 |

448 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Nuovo

- Nuovo

- Nuovo

Seamer for soft drinks, beer and carbonated soft drinks

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Vertical form-fill and seal machine of the “Economy” series

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

LRC-700 Combined Robotic Case Packer & Palletizing System

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

PP220 Horizontal Type Pre-Pouch Doypack Packaging Machine

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

GF series automatic plastic bottle filling and capping production line

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Filling and seaming groups for aluminium and tin plate cans

- Nuovo

- Nuovo

TPM 1000 fully automatic thermoforming packaging machine

- Nuovo

Heavy Duty Double Chambers Vacuum Packaging Machine J-V012W

- Nuovo

MC4TB High-speed wrapper for chocolate tablets and bars

- Nuovo

- Nuovo

- Nuovo

Machine for the production of thermoshrinking bags SA-V TVB

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT