- Nuovo

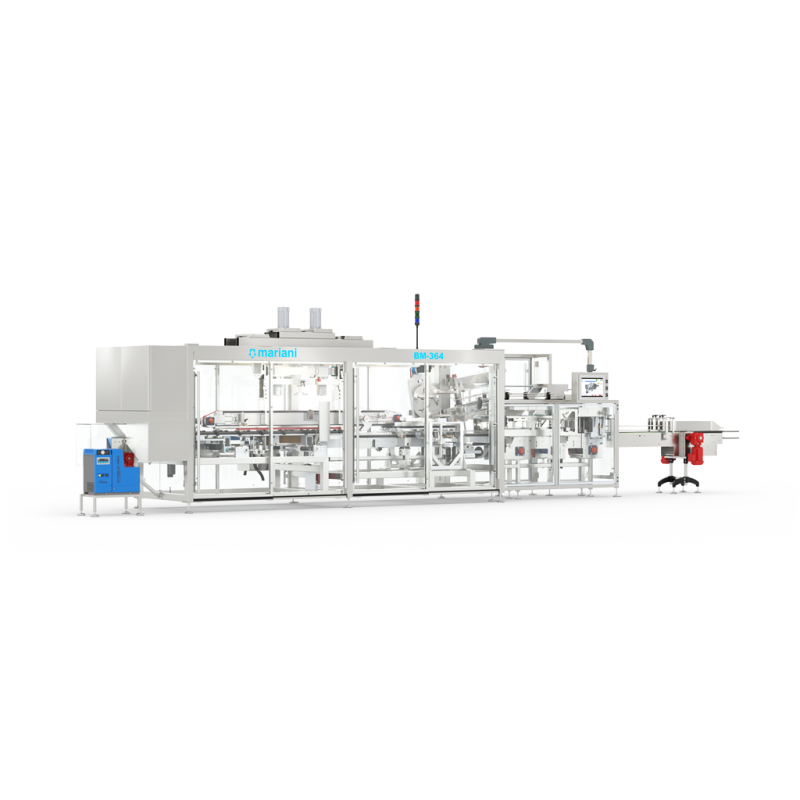

BM-364 Sleeve wrapping machine

Machine designed to wrap products like Jars, tin cans, bottles or similar containers with rigid bottom glued carton board.

Descrizione

Machine designed to wrap products like Jars, tin cans, bottles or similar containers with rigid bottom glued carton board.

It is a category of totally automated machinery of the BM series, a cinematic continuous-run plant designed for medium to high-speed packaging productions of stiff products in sleeves with wraparound cardboard, and heat-glued strips.

Operational principles

- Completely electronic machine controlled by independent brush-less motors, each motor mounted onto single guiding axes.

- The touch-screen control panel of the BM 364 sleeve wrapping machine has been updated and simplified to allow a fast and efficient operating method.

- The machine has been designed based on a “user friendly” interface concept, with text and graphics with instant explanation thanks to the support of the touch screen panel.

- During the format change operations, a “check-list” displayed on the panel guides the operator through each operation phase.

- In addition, the totally open framework of the BM 364 allows easy access for the operators and maintenance personnel.

- The enclosed base housing makes the cleaning operations easier, should there be any accidental fall of the product and/or liquids.

- The toothed transmission belts and the axes movement system reduce maintenance and allow high production rates.

- It is possible to raise the two driven belt units at machine’s entry to remove products and assist with the cleaning operation.

- The carton blanks magazine is loaded laterally with a controlled pressure advancing system.

- Carton blanks pick-up by means of suction cups adjusted manually and fitted with a venture pump.

Functional characteristics

- “Touch-Screen” operator panel to control the different operation phases and the application of the hot-melt glue.

- The servomotor technology, standard for this system, makes format changes smooth and simple and requires no tools. Control panel with display of the possible alarms during the production cycle and output rate indication. Week programme clock for automatic start-up and control of the glue applying station.

- Light signal with 3 colours to indicate: minimum quantity of carton blanks magazine, manual control, machine stopped.

- The visualisation of the operating process is displayed on a 19” 3-colour Touch-Screen operator panel which allows:

• data record recall of the packaging formats

• faults diagnostic guided through a visualisation of the system

• visualisation and assistance indications with remote connection facility via Ethernet

Technical data

Product types: Tin cans, jars, bottles or cylindrical containers

Product size: To be confirmed

Packaging format: Units of 3×2 – 4×2 Other formats available on request

Operating speed: 60.OOO c.p.h + 25%

Machine data

Carton blanks magazine: Capacity up to 2.500 blanks according to the blank thickness.

Frame and housing:

- Structure in stainless steel and anti-oxidant painted parts, lateral polycarbonate high resistance sliding guards of modern design over the entire machine height. Easy access to the main elements.

- Differentiated lubricating system according to the mechanical components to be lubricated.

- Differentiated lubrication depending on the mechanical components to be lubricated.

- Ejection system for not glued clusters.

Format change:

- From 5 to 10 minutes according to the packing arrangement.

- Pre-programmed format change-over components, removable without tools.

- Check-list for the format change visualised on the display.

- Format change values indicated on the machine. Automatic product feeding.

Machine dimensions: Length: from 6,5 m to 8 m (according to the multi-pack type). Width: 1,4 m x height: 2,6 m

Machine weight: From 4.000 to 5.000 Kg according to the multi-pack type

Electric requirements:

- 400 V, 50 hz, 15 kVa or according to customer’s specifications.

- Protection grade of electric panels ip 55, machine ip 65 Power requirement: 13 kw

Compressed air requirements: Pressure: 6 bar | Consumption: 30 m³/h

Applicable directives:

- Machinery directive 2006/42/ec.

- Electromagnetic compatibility directive 2004/108/ec low voltage directive 2006/95/ec.

Optional: Integration to cope with us regulation.

448 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

Vertical form-fill and seal machine of the “Economy” series

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

LRC-700 Combined Robotic Case Packer & Palletizing System

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Machine for the production of thermoshrinking bags SA-V TVB

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Heavy Duty Double Chambers Vacuum Packaging Machine J-V012W

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Filling and seaming groups for aluminium and tin plate cans

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Seamer for soft drinks, beer and carbonated soft drinks

- Nuovo

- Nuovo

- Nuovo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Nuovo

MC4TB High-speed wrapper for chocolate tablets and bars

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

TPM 1000 fully automatic thermoforming packaging machine

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

PP220 Horizontal Type Pre-Pouch Doypack Packaging Machine

- Nuovo

- Nuovo

- Nuovo

GF series automatic plastic bottle filling and capping production line

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT