- Nuevo

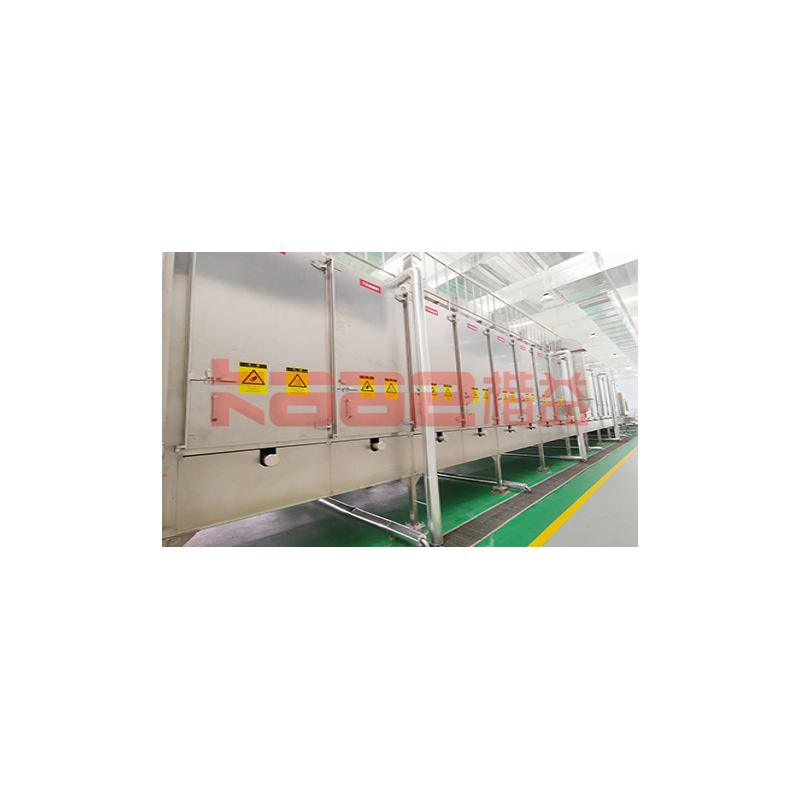

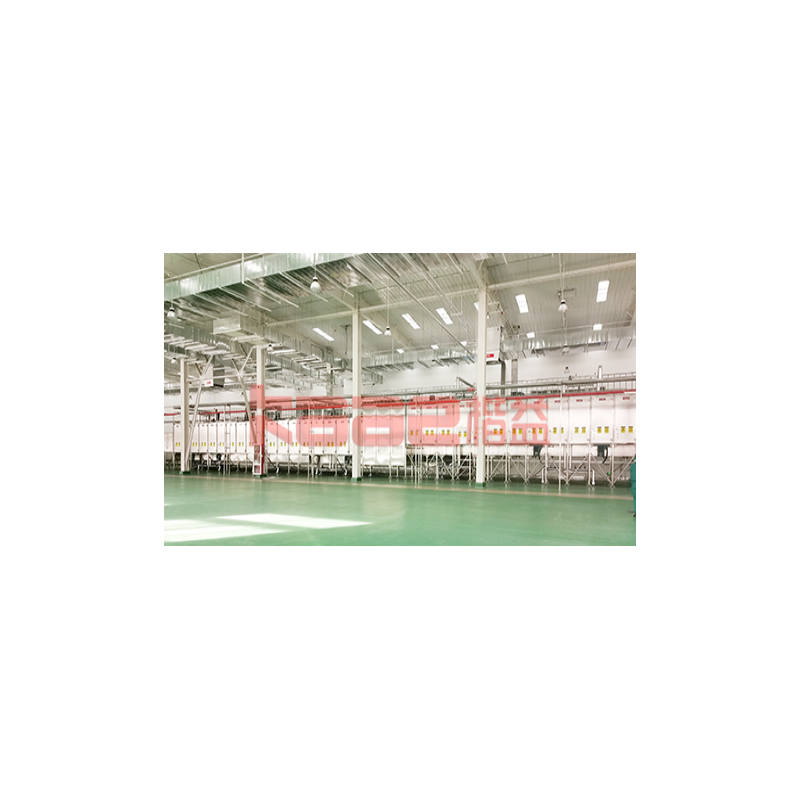

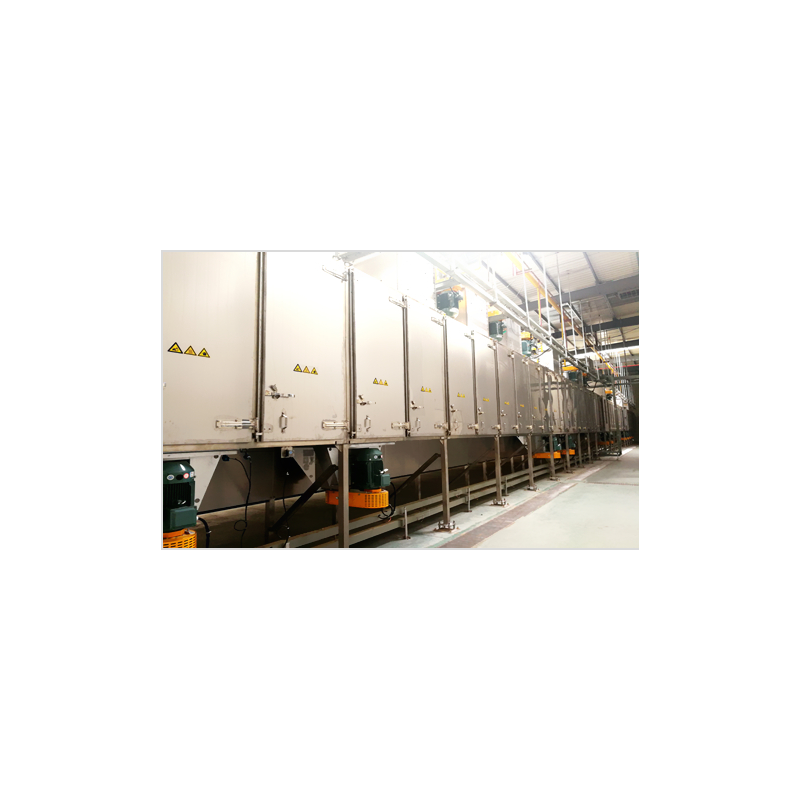

Intelligent bedplateconveyor dryer

Contract price

Intelligent bedplateconveyor dryer

UPC:

EAN13:

Descripción

Scope of application: most products suitable for different fields, such as:

1) the food field:

- a. Roasted seeds and nuts (walnuts, peanuts, almonds, macadamia nuts, seeds, pistachios, etc.)

- b. Fruits and Vegetables

- 1. roots: garlic, onions, ginger, etc.

- 2. fruit: jujube, medlar, plum, apricot, pear, peach and other granular fruits and vegetables.

- 3. vegetable department: (red / green) pepper, celery, sugar beet, carrot, cauliflower, broccoli and so on

- 4. preserved fruit (cranberry, blueberry, strawberry, cherry, Cherry Tomatoes, Taiping fruit, Begonia, apricot, pear, peach, etc.).

- c. leisure food (expansion and non expansion);

- d. grain and others

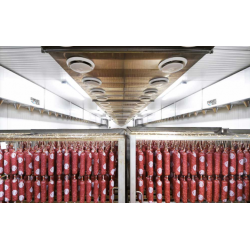

2) Pet food and aquaculture feed

- a. Pet food (dog, cat, etc)

- b. aquatic feed (all kinds of suspension, semi suspended and heavy materials, seafood and inland river products).

3) industry:

- a. synthetic rubber

- b. SAP (high water absorbent resin)

- c. Natural or artificial fiber

- d. Other industrial raw materials and semi raw materials

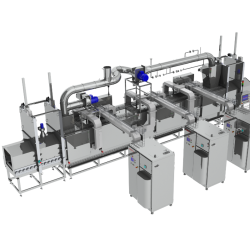

Principle of Drying Process

- 1. Alternative air-flow directions to reach optimum moisture uniformity

- 2. Corresponding to specific characteristics of different types of product, apply different air temperature, humility, air-flow direction and flowing volume at different drying stages to reach optimum drying efficiency and energy consumption.

- 3. Modular structure, not just improve onsite installation with shorten installation time, but ease adjustment of production capacity by additional modules added or removed;

Characteristics of specification

- 1. According to different drying characteristics of different materials,single layer/multilayer design is adopted to meet the requirements of different process design.

- 2. Process air temperature could be adjusted independently suitable for different requirement of drying process.

- 3. Allowing internal access to all areas, ease of cleaning

- 4. Fines self-cleaning effects all inside, NO deal corner.

- 5. Automated PLC recipe ensuresuniform distribution of air flow and temperature in each zone, and fully regulated humidity control on even drying across the full bed width.

- 6. The use of special bedplate conveyor structure, and the product contact is the food grade materials to ensure the safety of food.

- 7. The main body of the dryer is made of a multi section hot air circulation system, with high thermal efficiency.

- 8. Heat sources can be used in a variety of forms: coal, natural gas, electricity, etc.

- 9. A variety of heating methods can be used: hot air, steam, heat conduction oil and so on.

- Made from: Stainless steel

68 otros productos en la misma categoría:

- Nuevo

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LABORATORY MACHINE)

- Nuevo

Food drying cabinet CABINET MAK DRYER 7-14

- ¡Disponible sólo en Internet!

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT