- Nuevo

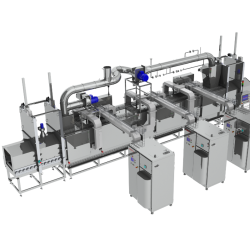

Fluid Bed Dryer systems

A continuous fluid-bed system is a machine in which a continuous flow of “wet” powder, granular or flakes material is conveyed over a perforated bed.

Descripción

Conveying of the product is done by means of a low-frequency, high amplitude shaker mechanism. The “Shaking” motion plug flow of the Tema fluid bed dryer, allows first-in, first-out drying of products and well-mixed fluidization, which covers the entire spectrum and is able to accurately control the spread of residence time.

The fluid bed dryer system blows hot drying air through the holes of a perforated plate. The wet particles are lifted from the bottom and cause the particles to behave as a fluid. The air velocity is adjusted to keep the moving layer of material fluidized.

Types of Fluid bed dryer systems

tema-process fluid bed dryers Shaking fluid bed

Shaking fluid bed dryer system

These are units for continuous operation and suitable for sticky materials with a wide particle size distribution. The shaking motion improves the fluidization and transport of any material within the fluid bed. Drying gas temperature up to 750 °C and product temperatures up to 400 °C are achieved.

tema-process fluid bed dryers Static fluid bed

Fluid bed dryer system

A fluid bed is an effective unit to thermally treat powders, crystalline products, pelletized or extruded materials. High heat and mass transfer are obtained as a result of the intimate contact between fluidizing air and product.

Static fluid bed dryers and coolers are ideal for products that are free flowing

Static fluid bed dryer system

units in continuous and batch type for more uniform materials that do not tend to agglomerate. It is possible to install submerged heat exchangers in a deep static bed. With submerged heat exchangers energy input is both from the fluidizing air as well as from the heat exchangers reducing the size of the equipment and limiting the exhaust air volume.

Advantages of continuous fluid-bed dryer systems

Low energy consumption compared to other type of dryers

Accurate control of the residence time, product is dried uniformly

Gentle on sensitive materials (no friction)

Low operating costs

Cooling section integrated in dryer

Handling of sticky products (from centrifuges or filters)

Small footprint

Process flexibility

Reliable system, less downtime

68 otros productos en la misma categoría:

- Nuevo

- ¡Disponible sólo en Internet!

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT