- Nuevo

Spray Dryers

Evaporator Dryer Technologies has the modern technology and know-how to design, engineer and supply evaporation.

Descripción

Spray Dryers

Evaporator Dryer Technologies has the modern technology and know-how to design, engineer and supply evaporation and spray drying systems in a variety of process configurations.

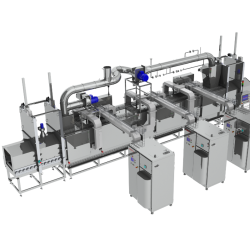

Spray Drying Systems - Main Component Configurations

Whey Drying Systems

Whey and Whey Permeate Spray Drying system. In this system configuration, product is exposed to low temperatures during the drying process to convert β-lactose to α-lactose crystals in whey or whey permeate. The result is powder that is non-hygroscopic and free flowing. Main components of this system include an evaporator, feed system, drying chamber, lactose conversion belt, vibrating fluid bed, cyclones and wet scrubber. This type of system is extremely energy efficient with energy costs up to 24 percent less per lb. of powder compared to traditional straight through spray drying methods.

Single-Stage

Spray dryer only is used when powder discharged from the drying chamber meets the desired characteristics without further processing.

Two-Stage

Spray drying chamber with a stationary or vibrating fluid bed mounted beneath the drying chamber for further drying and/or cooling. This configuration allows for optional powder fines return. Two-stage drying allows for gentler handling of the product therefore reducing product degradation. This system offers better drying economies than single-stage drying.

Three-Stage

Spray drying chamber with integrated fluid bed and external fluid bed. This configuration allows for optional powder fines return. Three-stage drying is a highly flexible processing system. The integration of fluid beds provides further control of drying parameters allowing production of more difficult to dry products. System advantages include improved particle agglomeration and reduced product degradation by using lower drying air temperatures. Three-stage drying offers the best drying economies by using the least amount of energy.

Auxiliary Equipment to Spray Drying Systems

Concentrate Heaters

Heat Recovery Units

Exhaust Air Heat Recovery

Over Pressure Venting

Fire Suppression System

Atomizing Nozzle Video Monitoring System

High Pressure Atomizing

Typical Products Dried on EDT Spray Drying Systems

Dairy Products

Whole Milk

Skim Milk

Butter Milk

Sweet Whey

Acid Whey

Whey Protein Concentrate

Whey Permeate

Lactose

Cheese Powders

Infant Formulas

Egg Products

Non-Dairy Products

Malto-Dextrines

Flavors

68 otros productos en la misma categoría:

- ¡Disponible sólo en Internet!

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT