- Nuevo

Radio Frequency dryers

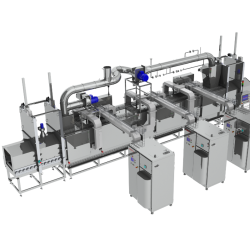

ARIES is a Radio Frequency dryer that ensures fast and efficient moisture removal and levelling, increasing shelf-life and cutting processing costs.

Descripción

ARIES is a Radio Frequency dryer that ensures fast and efficient moisture removal and levelling, increasing shelf-life and cutting processing costs. It also reduces checking problems, eliminates surface browning, enhances crispness and flavor, reduces Acrylamide formation.

Extend the shelf-life, cut costs

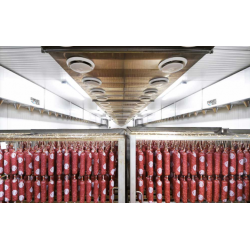

The drying process plays a decisive role in creating high-quality products. Radio Frequency dryers have been developed on purpose to remove the excess moisture content from many substrates in minutes, replacing slow and expensive conventional drying systems. The RF technology is particularly suitable for the post-baking drying of baked products (biscuits, crackers, crispbread, etc..). Indeed, final moisture reduction and levelling is a difficult task to achieve in baking ovens: due to the crust formation during baking, moisture evaporation takes about 60% of the energy of the entire process and about 30% of the overall oven length. Differently, Radio Frequency is selective towards water and ensures drying in minutes with no surface over-baking or excessive coloring. Hundreds of RF post-baking dryers have been installed in industrial bakeries in the last 40 years, making it the most popular RF drying application in the food sector.

HIGHER PRODUCT QUALITY

RF drying reduces checking problems, eliminates surface browning, enhances crispness and flavor, prolongs the shelf-life, reduces Acrylamide formation.

EASY INTEGRATION IN ANY PRODUCTION LINE

The reduced footprint of post-baking RF dryers guarantees a smooth and easy installation even in small production facilities. The modular design allows to increase the production capacity at a later stage. The PLC software ensures an easy and seamless integration into fully automated production lines.

BOOST PRODUCTION, SAVE MONEY

The desired final moisture content is achieved uniformly in a few minutes or even seconds, allowing at the same time a 20-30% increase in production capacity and huge savings in operating costs. The process is not affected by external ambient conditions.

ACCURATE PROCESS CONTROL

The RF power delivered by the machine can be easily adjusted and automatically controlled based on the specific needs of each particular product, thus ensuring an accurate moisture removal and the best quality results, minimizing at the same time human errors.

68 otros productos en la misma categoría:

- Nuevo

- ¡Disponible sólo en Internet!

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT