- Novo

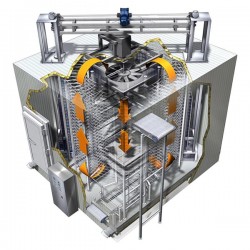

Tunnel pasteurizer

Contract price

Tunnel pasteurizer TP-HRW designed for thermal treatment of the product in the packaging, in order to increase its biological stability.

UPC:

EAN13:

Descrição

Capacity: from 500 till 60 000 bottles or cans/hour

Product: beer, kvass, juice, wine, carbonated and non-carbonated drinks, canned food

Number of temperature zones: from 7 till 10

Method of pasteurization: shower, shower-submersible

Method of pasteurization: shower, shower-submersible

Operating mode: automatic, semi-automatic

Heating source: steam, hot water, electricity

Dimensions depends of the capacity, the required temperature and container size. Pasteurizer is made in the form of the tunnel

Material: stainless steel AISI 304, AISI 316L, AISI 316Ti, AISI 321

- Whole process of pasteurization is fully automatic

- Registration of 8 pasteurization parameters

- Water exchange system between heating and cooling zones

- System of opening and fixing of the upper lids allows easier access and simplifies the cleaning

- Active container feeding system

- Overload protection system

- System of collection and return of condensate

- Effective and an independent spraying system in each zone

- Automatic monitoring and adjustment of PU

- Alarm system

- Creation of “recipes” for various products and containers formats

- Remote access via modem and the data transfer (profibus, internet, etc.)

Tunnel pasteurizers could be equipped with additional systems according to the customer request.

HERMIS company uses only high-quality materials and components manufactured in the European Union and meet all quality requirements:

- Gear reducers LENZE, SEW-EURODRIVE

- Pumps LOWARA, GRUNDFOS, KSB

- Steam valves BURKERT, SAMSON

- The temperature register ENDRESS+HAUSER

- Heat exchangers FUNKE, KELVION

- Active bottles transfer system REXNORD

- Electrical control system SIEMENS, MOELLER, OMRON

- Automatic control system SIEMENS

- Plastic modular belt REXNORD, MOVEX or stainless steel conveyor belt HERMIS, TWENTEBELT

- Air supply system SMC, FESTO

- Spray nozzles LECHLER

HERMIS provides tunnel pasteurizers with the following models and parameters:

- Reversible tunnel pasteurizer "TP-HRW-R" for small beverage plants from 500 bph - 4000 bph

- Tunnel pasteurizer "TP-HRW 5" for small beverage plants from 800 bph - 6000 bph

- Tunnel pasteurizer "TP-HRW 10/15" for middle beverage plants from 5000 bph - 15000 bph

- Tunnel pasteurizer "TP-HRW 20/60" for large beverage plants from 15000 bph - 60000 bph

- Double deck tunnel pasteurizer "TP-HRW-D" for large beverage plants from 24000 - 60000 bph

68 outros produtos na mesma categoria:

- Novo

Twist Spiral Pasteurizer & Cooler by WATER

- Novo

The Universal Full Water Immersion Retort

- Novo

Pasteurizers & Sterilizers

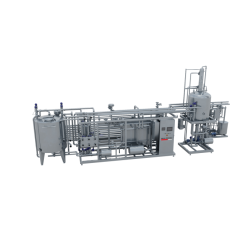

Plants for the preparation and pasteurization of ready sauces

Contract price

Plants for the preparation and pasteurization of ready sauces

- Novo

Mini pasteurizer - yoghurt maker (45 -120l)

- Novo

MIXWORKING BATCH - PASTEURISING PLANTS

- Novo

ICE CREAM MIX PASTEURISERS

- Novo

Flow Pasteurizer UTO

- Novo

Butter / cream Pasteurization Churn-Kneader

- Novo

Spiroaertex (packaged and unpackaged food)

- Novo

Risto milk pasteuriser

- Novo

Yogurt Maker for Mini dairy (200 - 500 l)

- Novo

LQ-BS Automatic Bottle-inverter Sterilizer

- Novo

- Novo

Universal-circulation system KK

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT