- Novo

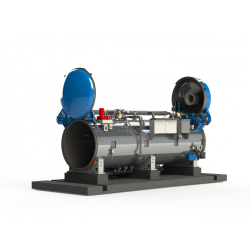

The Universal Full Water Immersion Retort

Various as our customer's requirements regarding capacity and sterilisation process - our range of full water immersion retorts: from the 2-cage autoclave for small batches of high quality "delicatessen" up to large capacity retorts for vegetable products in pouches.

Descrição

Product Quality - one system for all requirements

Variety of containers - flexible without compromises

Food safety - oxygen free processing

Energy contained in the storage vessel allows for an extremely short temperature come-up-time.

Water envelops the containers - even temperature penetration into the product from all sides.

Optimised water circulation system guarantees homogenous temperature distribution.

Buoyancy in full water immersion relieves sensible containers as semi-rigid trays, pouches etc.

Counterpressure control with steam in the storage vessel avoids pressure peaks and minimises stress to packaging material.

Containers are at no process phase in contact with air - oxidation of products is securely excluded.

Even, gentle but nevertheless fast cooling avoids thermal shock and post-sterilisation cooking effect.

High temperatures, transferred swiftly into the product, ensure that the required lethality effect (F-value) is obtained as fast as possible.

Various as our customer's requirements regarding capacity and sterilisation process - our range of full water immersion retorts: from the 2-cage autoclave for small batches of high quality "delicatessen" up to large capacity retorts for vegetable products in pouches.

The semi-immersion-rotary process, an option in each Stock Rotomat, meets highest requirements with reference to homogenous temperature distribution even with containers of a geometry, which otherwise impedes water throughflow.

17 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT