- Nuovo

- Nuovo

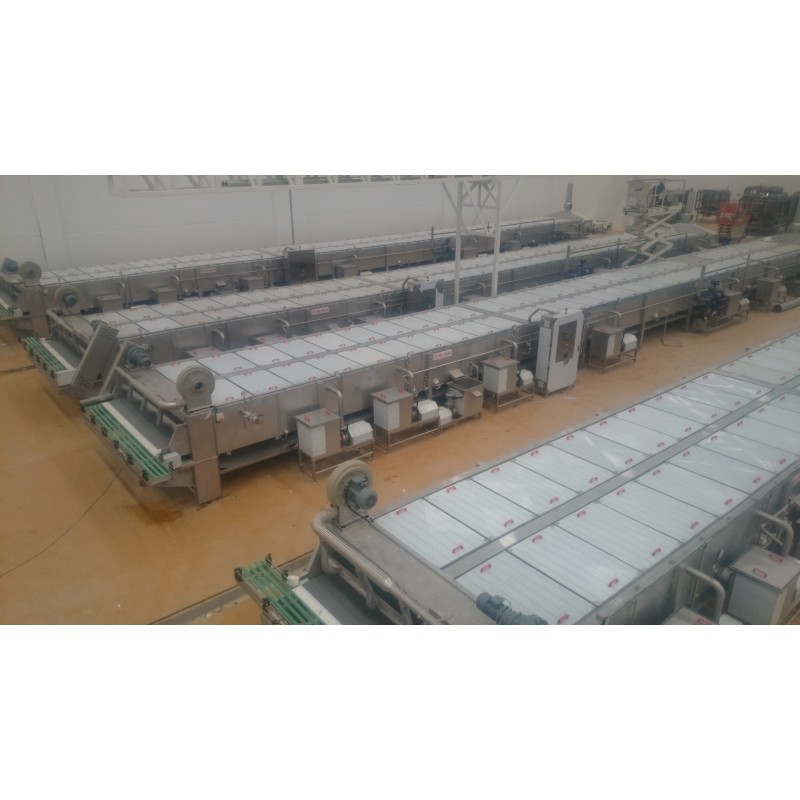

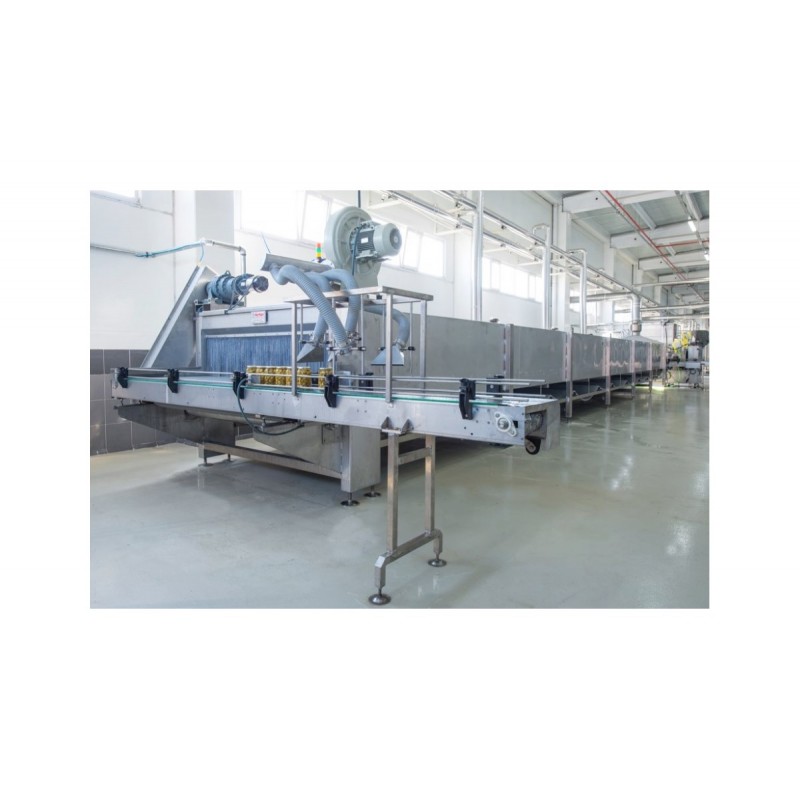

Pasteurization & Cooling Tunnel

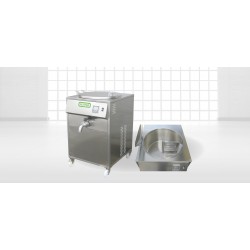

Pasteurizing and cooling Machine

Descrizione

Technicial Specifications

The water in the pools in the lower part of the machine is heated by plate heat exchangers and by means of the pumps, the upper part is sprayed with sprinklers (nozzles) on the cans or jars moving on the modular belt.

The controls of the KURTSAN Pasteurization Tunnel are controlled by a touch screen on the automation PLC panel. They are economical machines with minimum operating costs thanks to minimum operator requirement and proportioning controls.

Temperature, pasteurization time can read on automation panel.

The temperature and time are checked by ° C degree, and minute.

Steps; For each receipt can be prepared for each product. The water level is controlled by level probes, adjusted on the screen and it can be kept constant by using PLC control screen. The working level, unloading level run as automatically.

There are air knives installed on both sides of the belt in order to remove water top caps of products.

Description

Goal

It is used for pasteurizing and cooling products which hot or cold-filled such as cans, jars, bottles.

Material

AISI 304

Belt

Moduler type conveyor belt

Type

Available in shower or immersion types.

Control

PLC Automation

Usage

Easy to use with touch LCD display.

Sections

Kurtsan Pasteurizing tunnel, consist of inlet conveyor, section of pre-heating, section of pasteurization, progressive cooling, pre-cooling, the cooling and outlet conveyor.

Security

The heating system is fully otomatically operated by steam proportional valves in heating system at inlet steam, float Type condensate drain at outlet steam, heat control and level sensors for pool water.

68 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

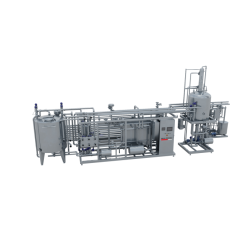

Plants for the preparation and pasteurization of ready sauces

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT