- Nuovo

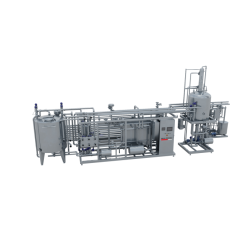

Flow pasteurizer

Due to its energy efficiency and careful thermal treatment of milk, the flow pasteurizer is the ideal way to pasteurize daily volumes over 1 000 l.

Descrizione

Especially in the production of drinking milk, our energy-efficient units have a heat recovery of 92 %. This way of heating milk saves the operator both heating and cooling energy.

A separator and a homogenizer can be easily integrated to the flow pasteurizer – also after commissioning. This will allow for the production of a wide range of dairy products with different fat contents and textures.

By connecting a special unit the holding time of milk can be extended up to 300 sec.

We design our flow pasteurizers to meet customers’ requests. The smallest unit has an output of 500 l/h. These pasteurizers can be heated with steam, electricity or with other heating systems such as oil-fired systems, gas central heating, wood heating, and combined heat and power systems. In addition, different heat sources can be combined.

All components relevant to safety (line recorder, anti leakage safety valve, plate heat exchanger for milk, measurement and control technology as well as sensors) that are installed in the flow pasteurizers built by A·S·T·A eismann GmbH comply with the German Federal Dairy Research Centre type testing, and have either EHEDG or FDA certification.

- Made from: Stainless steel

68 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

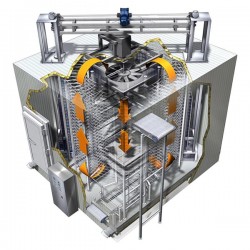

Plants for the preparation and pasteurization of ready sauces

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT