- Nuovo

Twist Spiral Pasteurizer & Cooler by WATER

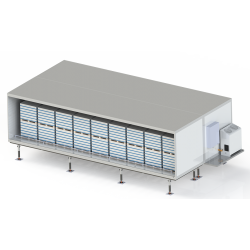

The ideal cooling system for pouches, sachets, cups, jars and lots of other different containers

Descrizione

Advantages

• SPACE SAVING – Very compact design too minimize the space occupied

• NO CONCRETE OR FLOORING – No need of any special flooring, neither concrete floors, nor civil work. We just need a flat floor!

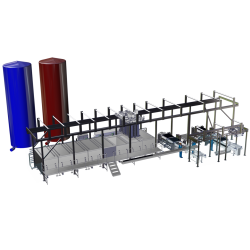

• VERY LOW WATER CONSUMPTION – The system recirculates all the water in its own tank. Due to the temperature controls and the logic applied, using a simple Cooling Tower and/or a Chilling unit, the only water wasted is due to the heat exhange with the containers. So it’s extremely low. A pump recirculates the water through a plate heat exhanger and the flow is integrated by a 3 ways valve automatically.

• POWER SAVING – Our Twist Spiral Water Cooler is designed to achieve your cooling time and outlet Temperature even just with fresh water or with cool water from a Cooling Tower.

• TOTAL FLEXIBILITY – We can accomodate mutiple lines inside the same tower, independently or separatly.

We can play with inlet and oulet locations in order to match all your requirements in term of space and utilities positioning

• LOW TENSION SYSTEM – Reduced belt wear and elongation thanks to low tension drive system. The belt is pulled by means of dynamic friction on the total length. Zero stress for the belt, which can perform in all the possible conditions

• WATER SPRAY EFFICIENCY – Water is sprayed in different conditions with different nozzles and disposition; each configuration is tailored for each specific application in order to optimize the exchange

• HIGH MECHANICAL RELIABILITY – The system almost needs zero maintenance. Simple and solid, it’s designed to operate in all the possible conditions and it’s manufactured for not stopping anytime

• NO CONTAMINATION – No belt lubrication, all the meachnical parts and pipings are out

• PERFECT INSULATION – The panels insulate perfectly both the Spiral Water Coolers and Pasteurizers. The tanks underneath are painted with a special aeronautic paint which is making the total system ideally insulated and safe.

Features

• Collecting tanks underneath and recycle pump positioned at the lower part of the spiral;

• Lateral protections in stainless steel very easy to open for washing, inspection and maintenance;

• Central Drum drive supported by roller bearings;

• “Stainless steel” or “Plastic” type flexible belt upon specific applications;

• Spiral’s structure made of stainless steel;

• HDMI PLC touch-screen with supervision system;

SERVING worldwide processors better and improving food processing technology by manufacturing a wide range of

TWP&TWC SOLUTIONS in Parma (Italy).

We are making available fully domestic made machinery and lines designed according the most modern European technology.

Spare parts and assistance available from Italy.

73 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

The Serap milk cooling tank Model First.SE

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT