- Neuf

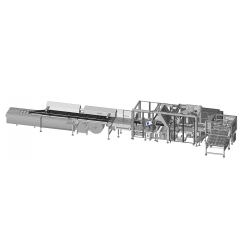

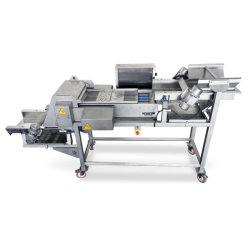

Industrial slicer A 560

You slice, weigh and portion a large product variety to target weight with just one device.

Description

Benefit from an automated hardware and software solution with the A560. You slice, weigh and portion a large product variety to target weight with just one device. Produce order-based and increase your profits slice by slice.

The automatic slicer A560 fulfills the needs of large-scale gastronomy/system gastronomy, large caterers, supermarkets/butcheries or industrial food processors. Fast product changes and short set-up times make your production flexible and economical. With its unique, integrated slicing and weighing function the A560 lowers give-away up to 15%. Irrespective of whether you process products to decorative stacks, shingles or portions. Also in terms of a location for the A560 you are free to choose – from production up to cleaning. The mobile and space-saving design makes it possible. Record your production data wit the industrial software _statistics.BRAIN. The ideal basis to control, document and evaluate your processes.

Area of Use

-The slicer for the entry in automatic production

Large-scale gastronomy/system gastronomy:

-Portioning of snack slice of cold meat

-Target weight slicing of cold cut portions to be served on a platter

Large caterers:

-Preparation of cold cut and cheese platters

-Slicing to exact target weight

Supermarket/butchery preparation room:

Pre-slicing of cold cuts and cheese for the counters an the self-service area

Feeding of small packaging machines

Industrial food processing:

-Producing convenience foods: In-line slicing

-Slicing of naturally grown products and small batches with minimal weight loss

Highlights

- Slicing, shingling or stacking of almost any kind of sausages/cold meats and cheeses - and usually without having to pre-frost

- Producing efficiently due to easy handling, space-saving design and fast product changes

- Hygienic working: Due to automatic production there is less contact with the product to be sliced which reduces the risk of germs

- Perfect target weight control with tendency control with to-the-slice precision

- Simple reporting of production parameters and line output with _statistics.BRAIN

- High investment protection due to a robust stainless steel design: Ideally suitable for intense production environments

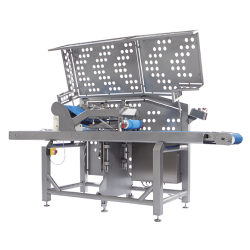

For perfect slices product must be optimally guided. Bizerba offers a broad portfolio of function variants. Should further adjustments be necessary, our Bizerba applications team will work on a solution.

Options:

- Integrated scale for portion weighing and weighing of individual slices

- Product fixation with hold-down device for perfect slicing results

- An optimal product holder is available for every product

- The right discharge conveyor is available for every production requirement

- TCP/IP-connection to _statistics.BRAIN

- Specific exchangeable slicing frames for a perfect hold of the product to be sliced before the blade: Perfect product slice image and depositing

- T belt: Wide belts for better depositing of small product

Technical data:

Voltage

-200-240 V 3-phase alternating current

-400 V 3-phase alternating current

Housing materials

-anodized aluminum

-Stainless steel

-Plastic

Installation area (L x W)

-1381 x 800 mm

Max. dimensions (L x W x H)

-2320 x 800 x 1835 mm

Blade diameter

-420 mm

Slicing performance

-With and without scale: 40 - 250 slices/min

Product size

-Round: Ø 40-180 mm

-Height: 30-180 mm

-Width: 50-210 mm

-Length: 600 mm

Slice thickness adjustment

-0.5-50 mm

IP rating

-IPx5

96 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT