- Nuevo

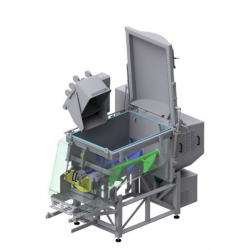

MIC Turbo – Mixer Granulator – Food

High shear wet granulation process is extensively used in pharmaceutical industry to transform fine heterogeneus powders into homegeneus blend.

Descripción

Features

PC with coloured touch screen panel.

Inteligent identification of raw materials.

Inteligent identification of operators.

Process edition by product.

Vacuum loading system.

Injector container for agglutinant.

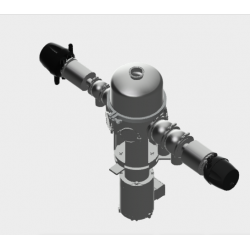

Peristaltic pump with volume control.

End point by torque measurement.

Graphics outline.

Printing reports.

Remote assistance by IP.

Automatic washing system.

Electric system according ATEX rules.

IN WALL design concept.

According to GMP guidelines.

FDA - Compliance / 21 CFR part 11.

FAT - SAT - Validation Documents.

APPLICATION: POWDERS MIXING WITH ADDITION OF LIQUIDS

The MIC Turbo-Mixer Granulator is a high-speed, intensive mixing system, which combines an extremely high shear force in the material to be mixed, with high impact and radial acceleration.

The synergy of this combination facilitates easy reduction of agglomerates and/or lumps, whilst allowing rapid addition of liquids to the mixture. This process therefore produces highly efficient dispersion in a very short period of time. As a result, an efficient and profitable mixing operation is achieved with optimal quality product delivery.

The MIC Automatic Plant features a modular design that allows the control, recording and performance of the following processes:

– Smart ID of raw materials (barcode reader)

– Automatic pre-weighing of raw materials Macro (silos /big bag)

– Weighing and loading stations

– Weighing and transportation bins

– Vacuum transportation systems

– Blower transportation systems

– Online raw materials gauge

– Homogeneous Mixtures (1 ppm) in 3 minutes, with automatic addition of liquids, semisolids, etc.

– Online screening of finished products

– Online metals detection

-Automatic feeding of packagers

– Finished product in bags

– Finished product in Big Bags

– W.I.P. Systems

184 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Continuous drum coating machine for adding spices and flavors AD

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT